consists of a multi-hole spray tip, a valve seat, and a

hydraulic lock, preventing the cam from retarding

needle valve extending the full length of the nozzle and

during injection. Fuel is directed by a passage in the

head to its seat, which is supported by a spring. The

advance housing end plug to the pressure side of the

high pressure is conducted from the fuel line to the

advance piston. The piston moves the cam

spray tip immediately above the valve seat. When the

counterclockwise (opposite to the direction of pump

valve needle is lifted vertically from its seat, fuel is

rotation). The spring-loaded side of the piston balances

sprayed into the combustion chamber.

the force of the power side of the piston and limits the

maximum movement of the cam. Therefore, with

In both the distribution pressurized type and the

increasing speed, the cam is advanced and, with

unit injection type of fuel injection systems for diesel

decreasing speed, it is retarded.

engines, the pumps and injector nozzle are operated by

cam-actuated mechanisms similar to the valve lifting

DISTRIBUTION PRESSURIZED INJECTOR

mechanisms of internal combustion engines.

NOZZLE.--The distribution pressurized types have

either a high-pressure pump that discharges fuel in a

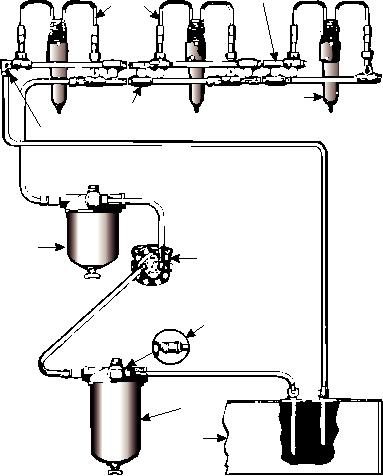

UNIT INJECTOR SYSTEM.--The unit injector

common header to which each fuel injector nozzle is

system combines the pump and the nozzle in one hous-

connected by tubing, or individual high-pressure

ing. There is one unit injector per cylinder (fig. 4-47).

pumps for each cylinder connected to the fuel injector

The fuel first passes through a primary filter

nozzle by tubing. In either case, the injector nozzle does

located between the fuel tank and the transfer pump,

not furnish the pressure necessary to overcome the

which may be of either the gear or the vane type. On the

cylinder pressure and spray the fuel into the cylinder,

discharge side of this pump is a secondary filter. Both

but only meters and times the fuel injection. A

filters have a drain cock at the bottom of the housing for

spring-loaded bypass valve on the header or on the line

removing water and dirt separated from the fuel. From

to the injector nozzle maintains a constant pressure and

the filter the fuel passes to the fuel manifolds. The

returns the excess fuel to the supply tank.

lower manifold is the inlet, from which the fuel flows

The spray or injection nozzle extends from the top

into the injector.

of the cylinder head down into the combustion area. It

OUTLET

JUMPER

MANIFOLD

LINES

FUEL INJECTOR

INLET MANIFOLD

RESTRICTED ELBOW

SECONDARY

FUEL

FILTER

FUEL

PUMP

CHECK VALVE

PRIMARY

FUEL FILTER

FUEL TANK

ASf04047

Figure 4-47.--Diagram of typical General Motors diesel fuel system.

4-35