amount of fuel that can be injected at rated load speed is

the hand priming port and resting against the priming

controlled by the torque screw; leaf spring adjustment

bypass spring. During hand priming, the pressure

has no effect.

differential across the transfer pump, caused by the

hand primer, forces the piston down, compressing the

As overload is progressively applied to the engine,

spring until the priming port (fig. 4-44) is uncovered.

the governor continues to hold the metering valve arm

Fuel bypasses the stationary transfer pump to fill the

in contact with the torque screw; therefore, the

system.

metering valve does not move during overload

operation. However, fuel delivery increases as the

When the piston is in the pressure regulating

engine speed drops because the charging ports remain

position, fuel forces the piston up the sleeve until the

in register for a greater length of time because of slower

regulating port or ports (fig. 4-45) are uncovered. Since

engine speeds. This allows more time for the charge of

the pressure on the piston is opposed by the regulating

fuel to pass through the metering valve, which is

spring, the delivery pressure of the transfer pump is

stationary; thus charging the cylinder with a larger

controlled by the spring rate, size, and number of

quantity of fuel.

regulating ports.

As the engine speed continues to drop and reaches a

The torque delivered by an engine increases

speed at which maximum torque is developed, the

progressively with a decreasing rpm caused by an over-

charge of fuel becomes great enough to force the

load. The torque continues to increase until it reaches

plungers outward far enough during each charging

its peak at a certain predetermined engine speed. This

cycle to bring the roller shoes into contact with the leaf

desirable engine feature is called torque backup. The

spring. This prevents further outward movement of the

torque backup, when the engine is overloaded, is

plungers; therefore, it limits the maximum amount of

caused primarily by the following three factors:

fuel that can be injected. From this you can see that the

More time is available for combustion of fuel.

maximum amount of fuel that can be injected during

Volumetric efficiency increases as engine speed

overload operation below peak torque is controlled by

the leaf spring adjustment.

decreases.

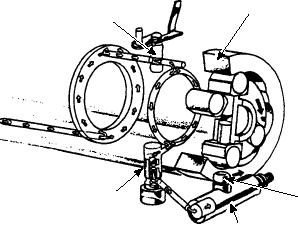

In the DC pump, the speed advance mechanism

Engine friction losses (and accessory loads)

provides controlled movement of the cam in the pump

decrease with engine speed.

housing to advance injection at high speeds. The rising

Since volumetric efficiency increases with

fuel pressure from the transfer pump increases flow to

decreasing engine speed, more fuel can be injected and

the power side of the advance piston (fig. 4-46). This

burned at the reduced engine speed, thus increasing the

flow from the transfer pump passes through a cut on the

torque output.

metering valve, through a passage in the hydraulic

head, and then by the check valve in the drilled bottom

To fully explain how torque control is ac-

head locking screw. The check valve provides a

complished when the pump is properly adjusted, it is

necessary to use an example, starting with a condition

where the engine is operating at high idle speed, and

METERING

CAM

VALVE

then progressively load the engine until engine rpm

RING

drops to peak torque speed.

When the engine is operating at high idle speed

with no load, the quantity of fuel delivered is controlled

by governor action on the metering valve. Torque screw

and leaf spring adjustment have no effect under this

condition.

As load is progressively applied, the governor

BOTTOM HEAD

LOCKING SCREW

action on the metering valve continues to control the

CAM

ADVANCE

quantity of fuel delivered until engine rpm drops to

PIN

ADVANCE

rated load speed. At this point, the governor has opened

PISTON

the metering valve enough to bring an arm on the valve

S P E E D A D VA N C E O P E R AT I O N

ASf04046

into contact with the torque screw, which prevents

further opening of the metering valve. The maximum

Figure 4-46.--Fuel flow in speed advance operation.

4-34