dispersed in the combustion space. Since penetration

requirements of the type of combustion chamber in use.

and atomization tend to oppose each other, a

Some chambers require very fine atomization; others

compromise in the degree of each is necessary in the

function with coarser atomization. Proper atomization

design of fuel injection equipment, particularly if

makes it easier to start the burning process, and ensures

uniform distribution of fuel within the combustion

that each minute particle of fuel is surrounded by

chamber is to be obtained.

particles of oxygen with which it can combine.

Atomization is generally obtained when the liquid

Methods of Fuel Injection

fuel, under high pressure, passes through the small

opening (or openings) in the injector or nozzle. As the

There are several types of fuel injection systems

fuel enters the combustion space, high velocity is

used in today's SE diesel engines. Some engine

developed because the pressure in the cylinder is lower

manufacturers make and install their own fuel injection

than the fuel pressure. The created friction, resulting

equipment. Others rely on manufacturers who

from the fuel passing through the air at high velocity,

specialize in fuel injection equipment and who design

causes the fuel to break up into small particles.

or modify their product to meet the requirements of the

engine manufacturer.

Creating Pressure

ROOSA MASTER FUEL INJECTION

A fuel injection system must increase the pressure

PUMP.--The Roosa Master fuel injection pump

of the fuel enough to overcome compression pressures

commonly used is the opposed plunger, inlet metering,

and to ensure proper dispersion of the fuel injected into

twin cylinder (Model DC), distributor type pump. The

the combustion space. Proper dispersion is essential if

main components are the drive shaft, distributor rotor,

the fuel is to mix thoroughly with the air and burn

transfer pump, pumping plungers, internal cam ring,

efficiently. While pressure is a chief contributing factor,

hydraulic head, end plate, governor, and the pump

the dispersion of the fuel is influenced, in part, by

housing with an integral advance mechanism. Early

atomization and penetration of the fuel. (Penetration is

advance mechanisms are attached to the pump housing

the distance through which the fuel particles are carried

and can be removed from the housing as a unit for

by the motion given them as they leave the injector or

servicing.

nozzle.)

The rotating members that revolve on a common

If the atomization process reduces the size of the

axis include the drive shaft, distributor rotor, and

fuel particles too much, they will lack penetration. Too

transfer pump.

little penetration results in the small particles of fuel

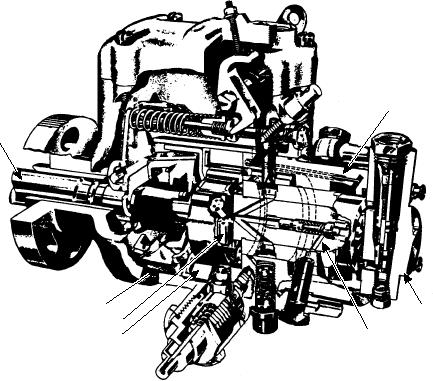

In the Model DC pump (fig. 4-37), the driving

igniting before they have been properly distributed or

member is the drive shaft that rotates inside a pilot tube

HYDRAULIC HEAD

DRIVE SHAFT

GOVERNOR

WEIGHT RETAINER

END PLATE

PLUNGERS

ROTOR

CAM RING

ASf04037

Figure 4-37.--Roosa Master fuel injection pump (Model DC).

4-30