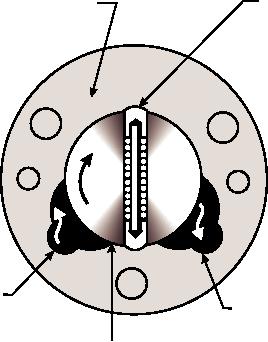

VA N E

ROTOR HOUSING

of fuel must be delivered to each cylinder for each

power stroke of the engine. Only in this way can the

engine operate at uniform speed with a uniform power

output. Smooth engine operation and an even

distribution of the load between the cylinders depend

upon the same volume of the fuel being admitted to a

particular cylinder each time it fires, and upon equal

volumes of fuel being delivered to all cylinders of the

engine.

Injection Control

A fuel system must also control the rate of

injection. The rate at which fuel is injected determines

the rate of combustion. The rate of injection at the start

INLET

should be low enough that excessive fuel does not

OUTLET

accumulate in the cylinder during the initial ignition

delay (before combustion begins). Injection should

ROTOR

ASf04036

proceed at such a rate that the rise in combustion

Figure 4-36.--Vanes and rotor in housing of a vane-type fuel

pressure is not too great, yet the rate of injection must

pump.

be such that fuel is introduced as rapidly as possible to

obtain complete combustion. An incorrect rate of

The remaining task to be accomplished by the fuel

injection affects engine operation in the same way as

system is to provide the proper quantity of fuel to the

improper timing. When the rate of injection is too high,

engine's cylinders. This is done differently by each

the results are similar to those caused by a too early

manufacturer and is referred to as fuel injection.

injection; when the rate is too low, the results are

FUEL INJECTION

similar to those caused by a too late injection.

Diesel fuel injection systems must accomplish five

Timing

particular functions: meter, inject, time, atomize, and

In addition to measuring the amount of fuel

create pressure. A description of these functions

injected, the system must properly time injection to

follows:

ensure efficient combustion so that maximum energy

METER. Accurately measures the amount of

can be obtained from the fuel. When the fuel is injected

fuel to be injected.

too early in the cycle, ignition may be delayed because

INJECT. Forces and distributes the fuel into the

the temperature of the air at this point is not high

enough. An excessive delay, on the other hand, gives

combustion chamber.

rough and noisy operation of the engine, and also

TIME. Injection of the fuel must start and stop

permits some fuel to be lost due to the wetting of the

at the proper time.

cylinder walls and piston head. This, in turn, results in

poor fuel economy, high exhaust gas temperature, and

ATOMIZE. Breaks the fuel up into fine

smoke in the exhaust. When fuel is injected too late in

particles.

the cycle, all the fuel will not be burned until the piston

CREATE PRESSURE. Creates the necessary

has traveled well past top center. When this happens,

high pressure for injection.

the engine does not develop its maximum power, the

exhaust is smoky, and the fuel consumption is high.

You can remember these functions by the initials

MITAC. All five of these functions are necessary for

Atomization of Fuel

complete and efficient combustion.

As used in connection with fuel injection,

Metering

atomization means the breaking up of the fuel, as it

enters the cylinder, into small particles that form a

Accurate metering or measuring of the fuel means

mist-like spray. Atomization of the fuel must meet the

that, for the same fuel control setting, the same quantity

4-29