unmeshed teeth, at the suction side of the pump, is

PLUG

carried by the teeth towards the sides. Then, the liquid

GASKET

is trapped between the tooth pockets and the casing, and

BOLT

SPRING

carried through to the discharge side of the pump. The

DRIVEN

BODY

GEAR

liquid entering the discharge side cannot return to the

RELIEF

suction side because the meshing teeth at the center

VALVE

DRIVEN

force the liquid out of the tooth pockets.

SHAFT

OIL

SEALS

Vane Pumps

STEEL

BALL

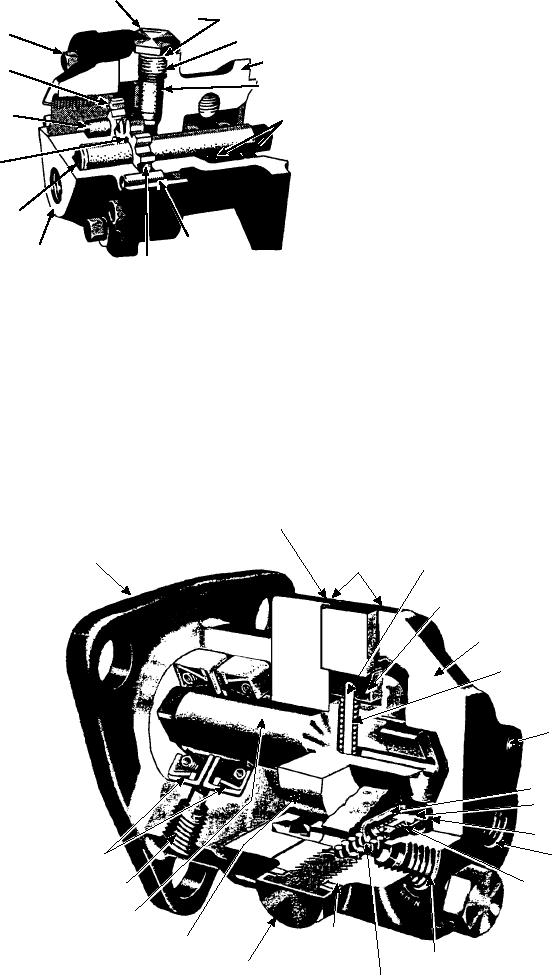

In the vane-type pump (figs. 4-35 and 4-36), a steel

DRIVE

rotor and shaft, one end supported in the pump cover,

SHAFT

revolve in the body, the bore of which is eccentric to the

DOWEL

rotor. Two sliding vanes are placed 180 degrees apart in

COVER

ASf04034

DRIVE

slots in the rotor, and are pressed against the body bore

GEAR

by springs in the slots. When the shaft is rotated, the

vanes pick up fuel at the inlet port and carry it around

Figure 4-34.--Typical gear fuel pump assembly.

the body to the outlet side, where the fuel is discharged.

Pressure is produced by the wedging action of the fuel

as it is forced toward the outlet port by the vane. A

spring-loaded relief valve is provided in the cover of the

Gear Pumps

pump, connecting the inlet and outlet ports. This valve

opens at a pressure of approximately 55 psi. Its purpose

The simple gear pump (fig. 4-34) has two spur

is to relieve excessive pump pressure, which will build

gears that mesh together; one is the driving gear, the

up if fuel lines or filters become clogged. When the

other the driven gear. Clearances between the gear faces

valve opens, fuel passes from the discharge side

and casing are only a few thousandths of an inch. When

(pressure side) to the suction side of the pump.

the gears turn, liquid in the spaces between the

PUMP BODY

MOUNTING

FLANGE

GASKET

VANE SPRING

GUIDE

VANE

PUMP COVER

VANE SPRING

DOWELS

VALVE GAUGE

RELIEF VALVE

VALVE SEAT

OIL SEALS

OUTLET PORT

VALVE SPRING

DRAIN

ROTOR SHAFT

GASKET

PUMP ROTOR

INLET PORT

RETAINER SCREW

VALVE RETAINER

ASf04035

SPRING

Figure 4-35.--Cutaway view of vane-type fuel pump.

4-28