Fuels may be polluted by dirt, rust, water, or by

includes refilling fuels, lubricants, coolants, hydraulic

accidentally combining with other types of petroleum

fluids, and other consumables (frequently used

products. If the products are to serve the purposes for

materials).

which they are intended, it is vital that you avoid such

You should be able to identify the types of fuels and

pollution. Dirt and water in fuels are primary causes of

lubricants, their specific use, and the method and

premature engine failure. When you handle fuels,

frequency of application. Proper selection of fuels is

cleanliness is essential.

also important. You do not put diesel fuel in a gasoline

engine or gasoline in a diesel engine. Yet, it frequently

GASOLINE.--Gasoline contains carbon and

happens.

hydrogen in proportions that allow it to burn freely and

produce heat energy. It evaporates (changes to a vapor)

Perhaps you have seen what happens to the wheel

at any temperature. Because gasoline vapors are

bearings in an automobile when they were not properly

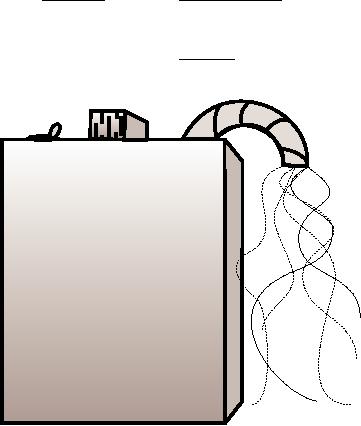

heavier than air, they sink to the ground (fig. 1-2). To

lubricated. In some cases the bearings were damaged

decrease the fire hazard of having the gasoline vapors in

due to lack of grease or by use of the wrong type of

a closed place where instant combustion could take

grease. This type of damage can be avoided if the wheel

place, the place in which gasoline is used SHOULD BE

bearings are inspected at regular intervals and if the

THOROUGHLY VENTILATED THROUGH OPEN-

correct lubricant is selected. Servicing modern support

INGS NEAR THE FLOOR.

equipment is important. A good knowledge of correct

fuels and lubricants makes the job easier and safer for

If all the potential heat energy contained in a gallon

the equipment.

of gasoline could be turned into actual work, a motor

vehicle could run many more miles on each gallon.

SERVICING PROCEDURES

However, only a small percentage of this heat energy is

turned into power by the engine. Most authorities

Usually, servicing support equipment is not very

consider the power losses within the engine to be as

complicated, but it is extremely important. You should

follows:

be able to determine how and why servicing can often

be so critical. For example, one item of equipment may

PERCENT OF

require several different types of oil, grease, or fluids.

ENGINE

POWER LOSS

Selection of the correct types and proper application to

Cooling system

35

the proper points can make the difference between a

Exhaust gases

35

piece of equipment that gives excellent performance

Engine friction

5 to 10

and one that is damaged beyond repair.

Total

75 to 80

Complete servicing details can be found in the

operation, servicing, and repair instructions section in

the MIM written for that particular type and model of

equipment. Servicing information can also be found in

the MRCs (maintenance requirements cards).

CONSUMABLES

GAS

The following text discusses some of the fuels,

lubricants, hydraulic fluids, and coolants used in

support equipment.

Fuels

Fuels for gasoline and diesel engines are

by-products of petroleum. Petroleum products include

gasoline, kerosene, diesel fuel, lubricating oils, gear

lubricants, and greases. Many different products are

added to the raw by-products to obtain a fuel that can

AS1f0102

perform well in modern equipment.

Figure 1-2.--Silhouette of gas vapors falling. Caution:

Gasoline vapors are heavier than air.

1-9