cylinder pressure with the boost pump. During aircraft

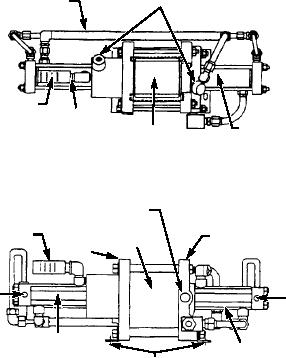

a large area reciprocating air drive piston directly

oxygen servicing, the oxygen module is grounded to

coupled by a connecting rod to a small area gas piston.

the nitrogen module and trailer grounding reel. The

The gas piston operates in a high-pressure gas barrel

following components are contained on or within the

section. Each gas barrel end cap contains

oxygen module (refer to figure 10-16 to locate the

high-pressure inlet and outlet check valves. (The boost

components on the module, and to figure 10-13 to trace

pump serves the same purpose as the pump and motor

oxygen flow):

assembly on the nitrogen servicing unit covered in

chapter 9. The internal design and operation of the

NOTE: The number in parentheses following a

oxygen boost pump are quite similar to those of the

component name refers to figure 10-13.

nitrogen servicing unit's pump and motor assembly.)

Oxygen Supply Pressure Gauge.--The oxygen

Figure 10-17 shows various features of the boost

supply pressure gauge (19) indicates the amount of

pump. The boost pump is physically located inside the

pressure in the oxygen cylinder (2). The gauge is

oxygen module. (See figure 10-16, rear view.)

located on the left corner of the oxygen module panel.

NOTE: The number in parentheses following a

(See figure 10-16, front view.) The oxygen cylinder

valve (4) must be open to read cylinder pressure.

component name refers to figure 10-13.

Selector Valve.--The selector valve (20) is a

P i l o t Va l ve s . -- Two b o o s t p u m p p r e s s u r e -

t h r e e - p o s i t i o n ( O F F / B O O S T / B Y PA S S ) , h a n d -

operated pilot valves (23) and (24), are located within

operated valve that controls oxygen flow to the boost

the oxygen module. (See figure 10-16, rear view.) The

pump (21), or it allows the oxygen to bypass the boost

pressure operated pilot valve (23) is a normally closed

pump. It also provides a means of shutting off the

(NC) oxygen module safety device, which prevents the

oxygen supply to the servicing system. The selector

boost pump (21) from operating with a high

valve is located on the left side of the oxygen module

compression ratio (in excess of 25:1). When the

panel. (See figure 10-16, front view.)

gaseous oxygen supply to the boost pump (21) inlet

port falls below 200 psi, the pilot valve (23) closes,

Boost Pump.--The boost pump (21) increases

shutting off the boost pump drive (nitrogen or

(boosts) the pressure of the gas leaving the oxygen

compressed air). The pilot valve (23) opens when the

cylinder for high-pressure servicing operations. It has

oxygen supply pressure to the boost pump (20) exceeds

a compression ratio of 25:1 to 36:1, depending on

300 psi.

oxygen cylinder pressure. The boost pump consists of

INTERCOOLER

BREATHER

DASH 30X

GAS

DASH 15X

AIR

BARREL

GAS

DRIVE

BARREL

VIEW A

GASEOUS NITROGEN INLET

AIR

LOWER

UPPER

DRIVE

CAP

CAP

HIGH

PRESSURE

OXYGEN

OUTLET

LOW

PRESSURE

OXYGEN

INLET

DASH 30X

DASH 15X

GAS

GAS

MOUNTING

BARREL

BARREL

BRACKET

ASf10017

VIEW B

Figure 10-17.--Oxygen boost pump.

10-30