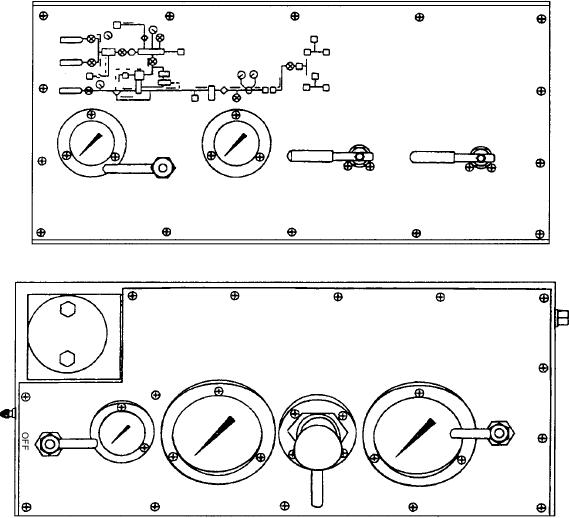

BOOST

VENT

NITROGEN

OFF

OFF

BOOST PUMP

BOOST PUMP

NITROGEN

BOOST PUMP

NITROGEN

DRIVE VALVE

DRIVE VENT

SUPPLY VALVE

DRIVE

SUPPLY

PRESSURE GAUGE

PRESSURE GAUGE

NITROGEN PANEL

OXYGEN

SERVICE

CONNECTION

OXYGEN

REGULATOR

VENT

BYPASS

OFF

OXYGEN

BOOST

VENT VALVE

OXYGEN

SELECTOR

SUPPLY

VALVE

REGULATOR INLET

PRESSURE GAUGE

REGULATOR OUTLET

PRESSURE GAUGE

PRESSURE GAUGE

OXYGEN PANEL

ASf10019

Figure 10-19.--Servicing controls and indicators.

NOTE: The number in parentheses following a

servicing a high-pressure system, ensure that the

component name refers to figure 10-13.

oxygen supply pressure gauge indicates greater than

450 psi. Install a fully charged oxygen cylinder if the

CHARGING AN EXTERNAL SYSTEM.--

gauge indicates less than 450 psi. If the pressure is

Before charging a system, prepare the oxygen

greater than 2,150 psi, use the pressure equalization

servicing unit as outlined below. Three methods can be

delivery method. If the pressure is less than 2,150 psi,

used to charge an aircraft system with the A/U26U-1:

use the boost pump.

direct servicing from the oxygen cylinder (referred to

2. Determine the pressure of the system to be

as the "pressure equalization" or "cascade" method);

charged.

boost pump using nitrogen drive; and boost pump

using air drive. Prepare the servicing unit for charging

3. Position the unit sufficiently close to the system

an external system as follows:

to be charged to avoid stretching the servicing

hose.

1. Perform a preoperational inspection on the

oxygen servicing unit in accordance with its

4. Attach the servicing hose and valve with the

preoperational checklist.

appropriate servicing adapter (figure 10-18) to

NOTE: When servicing a low-pressure (0 to 500

the oxygen service connection on the oxygen

psi) system, ensure that the oxygen supply pressure

module. (See figure 10-16, right side view.)

gauge indicates greater than 250 psi. Install a fully

5. Verify that all valves on the servicing unit are

charged oxygen cylinder if the gauge indicates less

either OFF or closed.

than 250 psi. If the pressure is greater than 650 psi, use

6. Ensure that the oxygen regulator on the oxygen

the pressure equalization delivery method. If the

module reads zero.

pressure is less than 650 psi, use the boost pump. When

10-33