SELECT

INRIGGER

TAGLINE

SELECT

STEERING

SELECT

REV/LOWER

DOWN

OUT

ON

LEFT

HOIST

FWD/RAISE

DIRECTION

LUFF

TRAVEL

RIGHT

PENDANT

SELECTED

EMERGENCY

SELECT

SELECT

STEERING

STOP

HOIST

ON

LEFT

LUFF

TRAVEL

RIGHT

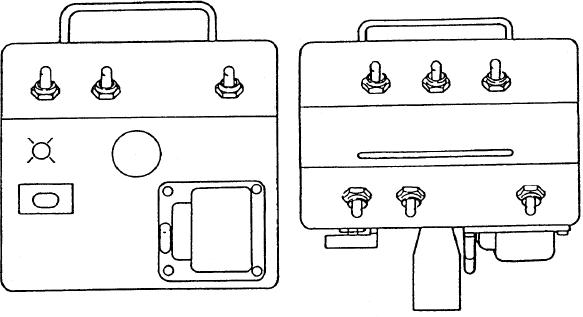

FRONT VIEW

TOP VIEW

ASf13003

Figure 13-3.--Pendant control box.

safety feature in case of malfunction during lifting

wheel assembly is removed from a smaller piece of

operations. The brake is electrically released when

support equipment. Because the wheel assembly

power is returned.

weighs 2,107 pounds, a forklift and sling must be used

to remove it from the crane. Once removed from the

The hook, or main hoist, is controlled by the

crane, the wheel assembly must be secured to the

operator and is powered by the same dc motor as the

forklift to keep it from breaking away.

luff control. The main hook has a limiting switch that

protects the hook, cable, and pulleys from damage by

Prior to removing a wheel assembly, be sure that

preventing the hook from traveling into the pulleys. The

you have the jack and chocks placed correctly. For

hydraulic brake system of the luff and hoisting

detailed instructions, refer to the technical manual for

differential is released upon selection of the operation

the equipment and to Support Equipment Tire and

needed at the time. This allows both systems to use one

Wheel Assemblies, NAVAIR 17-1-129.

motor and one set of gears.

NOTE: The AACC crash crane has no coil or leaf

The other two hooks located on the left and right

springs.

sides of the crane are called tag lines. These lines attach

HOISTING SYSTEM

to the load and prevent it from spinning freely when

lifting and moving. The tag lines are powered by a 5-hp

The crane is equipped with a non-rotating rigid

ac electric motor. When the tag lines are not used, the

steel boom that pivots on foot pins attached to the main

hooks are stowed on handles attached to the front of the

frame. To put it simply, the boom only moves up and

frame, one on each side.

down. The only way to move the boom left or right is by

using the steering controls to reposition the crane. The

MAINTENANCE OF CRASH CRANES

main hoist is moved by a single dc motor dedicated to

The scheduled maintenance intervals for the crash

that purpose.

crane are critical and must be followed to the letter. The

A single dc electric drive motor provides power to

appropriate maintenance requirements cards dictate the

raise and lower the boom through the luff/main hoist

time schedules and the proper lubricants and fluids for

control. This 60 hp motor receives its power from the ac

this unit. If scheduled maintenance procedures are not

generator after it is converted to dc via the MDC. The

completed properly, this complex crane could fail and

motor is equipped with a dc electric brake, which is

prevent the ship from launching aircraft or removing a

spring set when power is interrupted. This provides a

crashed or disabled aircraft from the recovery area.

13-5