with overcurrent protection. The braking mechanisms

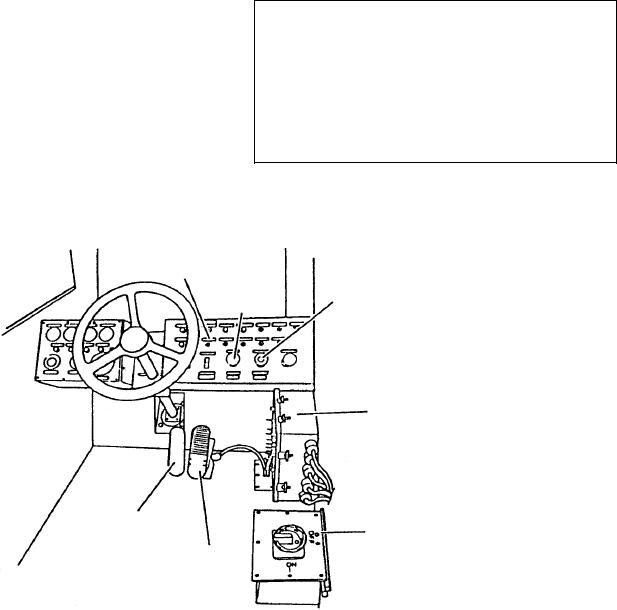

(fig. 13-2), and circuit breakers are located within easy

are activated when speed or movement demands are

reach of the operator. The high cab places the operator

removed. This allows adequate time for motor

in position to view the damaged aircraft and receive

slowdown. The motor drive cabinet receives 440-volt

signals from those on the deck.

ac, 60-Hz, 3-phase power from the ac generator. Then,

The accelerator pedal in the crash crane works

ac and dc power is available from the MDC.

similar to the accelerator pedal in a car. The same is true

of the brake pedal and steering. Both the brakes and

POWER TRAIN

steering are controlled by hydraulic systems.

The two 60 hp, dc-drive motors are identical, but

The crane can be operated from outside the cab

coupled differently. The mid-drive motor is coupled to

from a pendant control box (fig. 13-3) located on the

the differential via a universal joint coupling. The rear

left side of the crane, just aft of the forward wheel

power-train motor is connected to the differential drive

assembly (fig. 13-1). A fiber optic cable connects the

via a coupling. The differential carriers are suspended

pendant box to the crane. When using the pendant

within the structural frame. Unlike the differential in a

control system, the operator walks beside or behind the

tow tractor, however, they carry no radial loads. Instead,

crane, and controls it through the use of toggle

switches. Maximum speed during pendant operation is

they are used to transmit torque to the wheels. The

outputs of the differential carriers are coupled to the

limited to about 1 mile per hour.

planetary wheel drives via couplings connected to

NOTE: To learn more about fiber optic cables,

high-torque universal joint drive shafts.

refer to Navy Electricity and Electronics Training

Series (NEETS), Module 24, Introduction to Fiber

Optics.

WARNING

MOTOR DRIVE CABINET

The dc motors weigh 1,675 pounds each, and

each differential weighs 250 pounds. For this

The motor drive cabinet (MDC) is located on the

reason, removal and replacement must be done

left side and under the cab. The cabinet contains

with great caution. Refer to the technical manual

controls for the hoist, rear drive axle, and mid rear drive

for approved procedures.

axle. The motor drive logic responds to cab and remote

controls protected by various control mechanisms. The

Except for accommodations for its size, an AACC

microprocessor-driven current control provides timing

wheel assembly is removed in the same way that a

and firing commands to assure smooth motor operation

THROTTLE

SWITCH

TRAVEL

DIRECTION

LUFF/HOIST

SWITCH

SWITCH

24 VDC CIRCUIT

BREAKER

PANEL

BRAKE

PEDAL

440 VAC POWER

DISCONNECT SWITCH

ACCELERATOR

PEDAL

ASf13002

Figure 13-2.--Operator's cab.

13-4