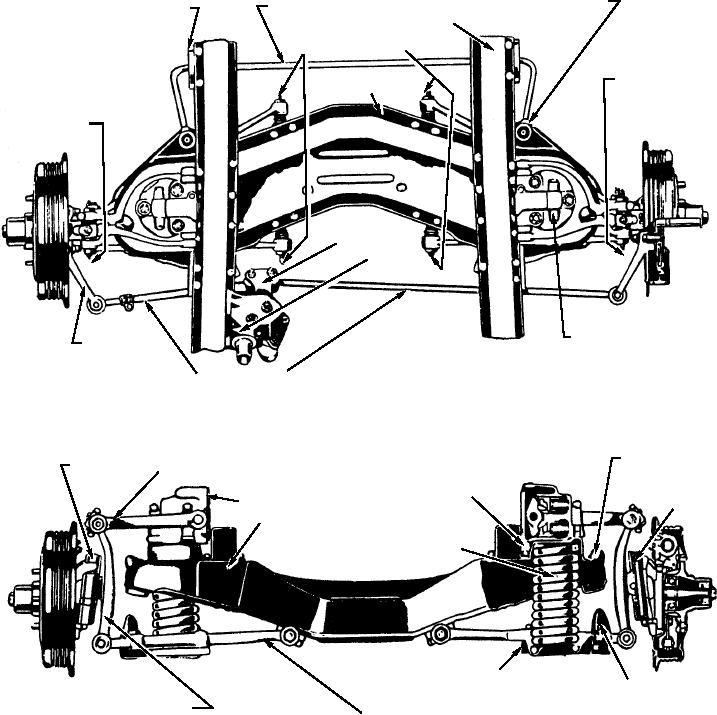

STABILIZER SHAFT MOUNTING

STABILIZER ATTACHMENT TO

AT LOWER SPRING SEAT

STABILIZER SHAFT

SIDE RAIL (RUBBER-INSULATED)

SIDE RAIL

GREASE FITTINGS

FRONT

GREASE

CROSSMEMBER

FITTINGS

GREASE

FITTINGS

PITMAN ARM

STEERING

GEAR

TOP MOUNT

STEERING

OF SHOCK

KNUCKLE ARM

DUAL TIE RODS

REBOUND

STEERING

UPPER CONTROL ARMS (UPPER WISHBONE)

BUMPER

KNUCKLE

UPPER SPRING

SEAT

SHOCK ABSORBER

KING PIN

FRONT CROSSMEMBER BRACE

COIL SPRING

LOWER SPRING SEAT

COMPRESSION

BUMPER

STEERING KNUCKLE SUPPORT

LOWER CONTROL ARMS (LOWER WISHBONE)

ASf02004

Figure 2-4.--Coil spring suspension.

Most shock absorbers used today are hydraulically

repaired; it can only be replaced when it becomes

operated, and their operation is easy to understand.

inoperative.

When the springs are flexed, liquid hydraulic fluid

Shock absorbers are usually attached to the

within the shock absorber is forced through a small

vehicle, as shown in figure 2-5, view A. Rubber

opening by a piston. Since liquids cannot be

mountings are used to fasten shock absorbers to the

compressed, the movement of the piston is controlled

frame and axle to eliminate wear and noise. Most

by the rate of flow of the hydraulic fluid through the

shocks can be replaced by removing the hardware that

opening. The tube shock absorber, as shown in figure

holds them in place. The hardware may be bolts at both

2-6, is used on automotive equipment and most types

ends of the shock absorber or, in some styles, the shafts

of support equipment requiring shocks. The tube shock

are threaded and washers and nuts hold them in place.

absorber is a self-contained unit that cannot be

2-5