FILLER PIPE

leaks, they should not be welded or repaired with or

TA N K U N I T O F

ELECTRIC FUEL GAUGE

near an open flame until all traces of fuel and fuel

vapors have been completely removed from the tank.

BAFFLES

ASf04003

WARNING

FUEL LINE

Before attempting to make any repairs to a

CONNECTION

CORK

MOUNTING

fuel tank, always consult with the shop supervisor

TO CARBURETOR

F L O AT

FLANGE

for specific instructions on all safety precautions

to be observed. Remember that fuel tanks can be

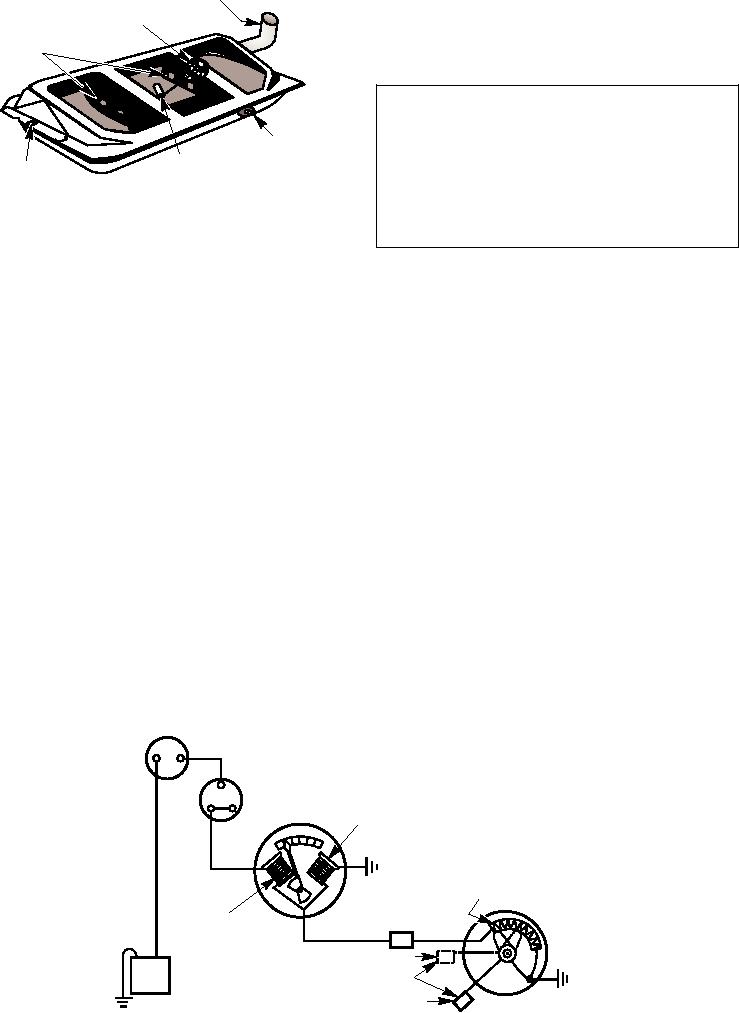

Figure 4-3.--Fuel tank with top cut away.

extremely dangerous.

construction of the equipment. Figure 4-3 shows the

Fuel Gauges

general construction of a fuel tank used on automotive

equipment. Most fuel tanks are of similar construction.

The fuel gauge is a signaling system that indicates

They are usually made of rust-resistant sheet metal, and

the amount of fuel in the tank. Most fuel gauges are

have an inlet or filler pipe and an outlet. The outlet, with

electrically operated and are composed of two units: the

a fitting for the fuel-line connection, may be in the top

gauge itself, which is mounted on the instrument panel

or side of the tank. The lower end of the outlet pipe is

of the vehicle; and the sending unit, which is mounted

placed about one-half inch from the bottom of the tank

on the fuel tank. An electrical fuel gauge normally

so that any sediment that collects in the tank will not be

operates only when the ignition switch is turned on.

carried to the carburetor. Baffle plates may be placed

The tank unit of the balancing coil-type fuel gauge

inside the tank to reinforce the sides and bottom and to

(fig. 4-4) has a float and arm assembly connected to a

prevent the fuel from surging or splashing. A drain plug

sliding contact. As the fuel level in the tank changes, the

is placed in the bottom so that the tank can be drained

position of the contact changes on a rheostat winding,

and cleaned. The fuel tank must be equipped with an air

thus varying circuit resistance and resulting current

vent. This vent is usually located in the cap of the inlet

flow. The unit on the instrument panel contains two

pipe.

magnetic coils (limiting coil and operating coil) and a

Some vehicles, especially aircraft tow tractors, may

permanent magnet, which is attached to the gauge

have more than one tank. On these vehicles, the

needle. When the fuel tank is empty, the limiting coil is

auxiliary tanks are interconnected, and the flow of fuel

stronger than the operating coil, thus the magnet is

from one or more of the tanks may be turned off.

drawn toward it and the needle reads EMPTY on the

Fuel tanks give little or no trouble, and, as a rule,

gauge. As the tank is filled, the operating coil becomes

require no servicing other than an occasional draining

stronger, attracting the magnet and moving the needle

and cleaning. However, if they are punctured or develop

toward the F or FULL position.

IGNITION SWITCH

GAUGE

OPERATING

F

COIL

E

LIMITING

RHEOSTAT

COIL

CONNECTOR

PARTLY FULL POSITION

FLOAT

BATTERY

EMPTY POSITION

SENDING UNIT

ASf04004

Figure 4-4.--Coil-type gauge circuit.

4-4