Fuel pumps are classified as positive and

During the suction stroke of a mechanical fuel

nonpositive diaphragm. The positive type continues to

pump, the rotation of an eccentric on the camshaft

pump fuel even when the carburetor bowl is filled, and

moves the pump operating arm, which pulls the

thus requires a method of bypassing the fuel back to the

diaphragm lever and the diaphragm downward. This

tank. The nonpositive diaphragm pump is the one

downward motion against the pressure of the

usually found in gasoline engines. It delivers fuel to the

diaphragm spring produces a vacuum in the pump

carburetor only when it is needed for the requirements

chamber. The vacuum holds the outlet valve closed,

of the engine.

while atmospheric pressure pushes the inlet valve open,

and fuel is delivered from the supply tank. The fuel

One type of electric fuel pump uses a motor to drive

flows through the inlet up through the filter screen, and

a set of gears, impeller, or centrifugal rotor (fig. 4-7),

down through the inlet valve into the pump chamber.

and is installed directly in the tank compartment. The

During the return stroke, the diaphragm is forced up by

inlet of the pump is submerged in the fuel. This is a

the diaphragm spring, the inlet valve closes, and the

positive displacement pump, and return lines are

outlet valve is forced open. This action allows the fuel

necessary to bring excess fuel back to the tank.

to flow through the outlet to the carburetor.

FUEL LINES

The diaphragm operating lever is hinged to the

pump arm at the arm pivot so that it can be moved down

Fuel lines connecting the various units of the fuel

but cannot be raised by the pump arm. The pump arm

system have traditionally been made of copper tubing.

spring makes that arm follow the cam without moving

However, copper tubing is being replaced by steel

the lever. The lever is moved upward only by the

tubing, which is rustproofed by copper or zinc plating.

diaphragm spring. The pump, therefore, delivers fuel to

For more information about cutting and fitting tubing,

the carburetor only when the fuel pressure in the outlet

refer to Use and Care of Hand Tools and Measuring

is less than the pressure maintained by the diaphragm

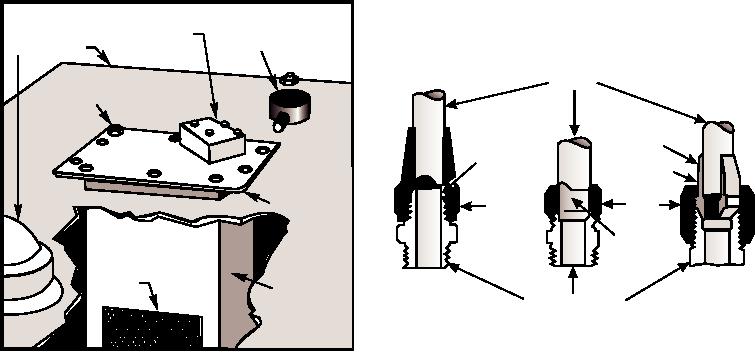

Tools, NAVEDTRA 14256. Three kinds of fittings are

spring. This condition arises when the fuel passage

shown in figure 4-8. These are the flared, compression,

from the pump into the carburetor float chamber is open

and soldered types. Of the three, the flared fitting is

and the float needle valve is not seated. The carburetor

most common.

float and needle valve control the fuel level in the

carburetor. On some fuel pumps, a dome-shaped air

Fuel lines are placed away from exhaust pipes,

chamber is added to smooth out the pulsation (surging)

of fuel being pumped.

cause vapor locks. They are attached to the frame,

engine, and other units so that the effects of vibration

will be minimized. Fuel lines should be free of contact

ELECTRICAL

with sharp edges that might cause wear. In places of

FUEL GAUGE

FUEL

CONNECTOR

FILL

SENDING UNIT

excessive movement, as between a vehicle frame

TA N K

PIPE

TUBES

FUEL

OUTLET

SOLDERED

FLARE ON

HERE

TUBE END

SLEEVE

NUT

GASKET

NUT

BALL

SLEEVE

(FERRULE)

A

C

F I LT E R

FUEL PUMP

CONNECTORS

HOUSING

ASf04008

B

ASF04007

Figure 4-8.--Types of fittings used on fuel lines. (A) Flared.

(B) Compression. (C) Soldered.

Figure 4-7.--Tank unit type of electric pump.

4-6