procedures and any specifications, clearances, or

outlet to the radiator if necessary, and remove the outlet

retaining cap screws. The thermostat can then be

tolerances pertinent to the job.

removed and checked for condition and operation. If it

When you replace a pump, install a new gasket.

is excessively rusted or bent, or if the valve is not

Make sure the mating surfaces are clean and smooth.

tightly closed, the thermostat must be discarded.

The application of sealer to both sides of the gasket is

If the thermostat appears to be in good condition,

often recommended. Then, after refilling the system,

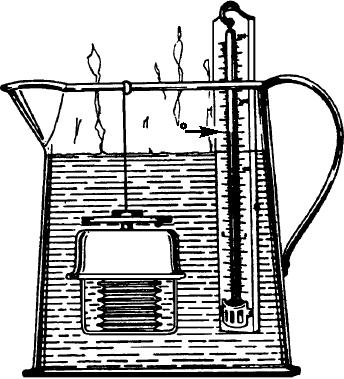

its operation can be tested, as shown in figure 5-11.

the pump should be checked for leaks, noise, and

The thermostat is suspended in a container of water

proper operation.

together with a high-temperature thermometer. Then,

Fan and Belt

by heating the container on a stove or hot plate, the

temperature at which the thermostat begins to open, as

A bent or distorted fan or one with a loose blade

well as the full-open temperature, can be determined.

should be replaced. Where the fan is merely loose on

If the thermostat fails to respond at specified

its mounting, you can tighten it. Loose fan belts can be

temperatures, it should be discarded. Specifications

adjusted for proper tension, usually by shifting the

vary on different vehicles, but on one popular make,

generator on its mounting. A common method for

the opening temperature is 180 to 185F, and the

measuring belt tension is to press down on the belt at a

full-open temperature is 200 to 202F. If the tests are

point midway between the generator and fan pulley;

satisfactory, the thermostat can be reinstalled. A new

then measure the amount of deflection. The amount of

gasket, or gaskets in the case of some V-8 engines,

d e f l e c t i o n w i l l va r y a n d s h o u l d b e s e t t o t h e

should be used and the cap screws tightened to the

m a n u fa c t u r e r 's s p e c i fi c a t i o n . T h e a m o u n t o f

specified torque. Then, the cooling system can be

deflection will depend on whether the belt is new or

filled and the engine operated to check for leaks as well

used and the distance between the pulleys. The normal

as proper thermostat action.

adjustment of the belt is measured between the two

You should now have a good understanding of the

pulleys furthest apart. The belt should have no more

service and repair requirements that pertain to cooling

than one-half deflection between the two pulleys.

systems in general. However, it is good to remember

A belt adjustment that is just tight enough to

that specific procedures or those peculiar to the system

prevent slipping may be considered correct. A belt that

on a particular vehicle will require reference to the

is too tight can cause the generator or alternator

bearing to wear rapidly. A belt that is too loose may

squeak when the engine is accelerating. When a belt is

misaligned, a squeak may occur at idle speed.

Correction can be made by using spacers on the

accessories or by filing brackets. However, if the

squeak is caused by a non-uniform groove or eccentric

pulley, the pulley should be replaced.

Replacement of a defective belt is usually made by

185

loosening the generator mounting bolts and the

generator adjusting arm and moving the generator

closer to the engine. The belt can then be removed over

the fan and a new one installed and adjusted.

Thermostat

There are no repairs or adjustments to be made on

the ordinary thermostat. The unit must be replaced if it

fails to operate properly. The temperature at which the

thermostat opens is very important and should be

t e s t e d w h e n eve r t h e c o o l i n g s y s t e m o p e r a t i n g

temperature indicates the need. To remove the

ASf05011

thermostat, drain the coolant until its level is below the

Figure 5-11.--Testing a thermometer.

thermostat, remove the hose connecting the thermostat

5-14