Oil Pressure Gauge

by the pump's drive shaft, which, in turn, actuates the

other gear mounted on a stub shaft. The two gears are

The oil pressure gauge is mounted on the

in mesh and rotate in opposite directions. Oil is picked

instrument panel of the vehicle. Marked off on a dial in

up in the spaces between the gear teeth and the

psi, the gauge indicates how regularly and evenly the

housing. This oil is then carried around to the pump

oil is being delivered to all vital parts of the engine, and

outlet where it is discharged. Pressure is developed

because of restrictions in the system caused by closely

warns of any stoppages in this delivery. Pressure

mated parts in the engine and pump. The gear pump

gauges may be mechanical or electrical. In the

may be driven directly from the camshaft or indirectly

mechanical type, the gauge on the instrument panel is

by the distributor.

connected to an oil line tapped into the main oil supply

passage leading from the pump. The pressure of the oil

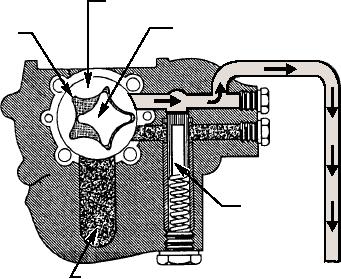

ROTARY PUMP.--The rotary pump (fig. 5-13)

in the system acts on a diaphragm within the gauge,

has an inner rotor with lobes that match similar shaped

causing a needle to register on a dial. In the electrical

depressions in the outer rotor. The inner rotor is off

type, the oil pressure operates a device on the engine

center from the outer rotor. As the inner rotor turns, it

that signals electrically to the pressure gauge, which

turns the outer rotor with it. As the two rotors turn, the

indicates the oil pressure.

openings between them are filled with oil. This oil is

forced out from between the rotors as the inner rotor

Some of the vehicles brought into the shop will not

lobes enter the opening in the outer rotor. As you can

be equipped with an oil pressure gauge, but will have

see in figure 5-13, the inner rotor lobes have very little

electrically operated warning lights on the instrument

clearance as they approach the discharge. This allows

panel, which flash on and remain lighted to indicate

the oil to be pressurized prior to discharge.

low oil pressures.

As a safety factor to assure sufficient oil delivery

Oil Strainers

under extreme operating conditions, the oil pump is

designed to supply a greater amount of oil than is

Most engines use at least one oil strainer or screen

normally needed for adequate lubrication. This

in the lubrication system. The strainer must have a

requires that an oil pressure relief valve, usually

mesh suitable for straining out undesirable particles

incorporated in the pump, as shown in figures 5-12 and

from the oil and yet pass a sufficient quantity of oil to

5-13, be used in the system to prevent excessive oil

the inlet side of the pump. The strainer is located so

pressure, especially at high speeds or when the oil is

that all oil entering the pump from the oil pan must flow

cold. The relief valve has a spring-loaded ball or

through it. Some screen assemblies also incorporate a

plunger that is forced off its seat when the desired

safety valve, which opens in the event the screen

pressure, which ranges from 30 to 50 psi, is reached,

becomes clogged, thus bypassing oil to the pump.

allowing the excess oil to be delivered to the inlet side

Strainer assemblies may be either the floating or the

of the pump or to return to the crankcase through a

fixed type.

drilled passage.

DRIVEN ROTOR

DRIVING ROTOR

OIL PUMP

PRESSURE

RELIEF

VALVE

ASf05013

INTAKE

Figure 5-13.--Rotary oil pump.

5-17