OPENING

AIR

troughs underneath the connecting rod bearing caps.

VA LV E

These troughs are kept filled by the oil pump, which

COVER

delivers the oil through nozzles.

CRANKCASE VENTILATION

There are two reasons for crankcase ventilation

during normal operation. It removes gasoline and

B R E AT H E R

water that trickle into the crankcase during the normal

TUBE

process of combustion; such gas and water mixes with

the oil and forms a pasty sludge if allowed to remain in

the crankcase. Ventilation also allows the crankcase to

breathe in order to eliminate excessive pressure in the

crankcase.

There are two methods of eliminating gasoline and

water from the crankcase--the non-positive method

and the positive method. The non-positive method

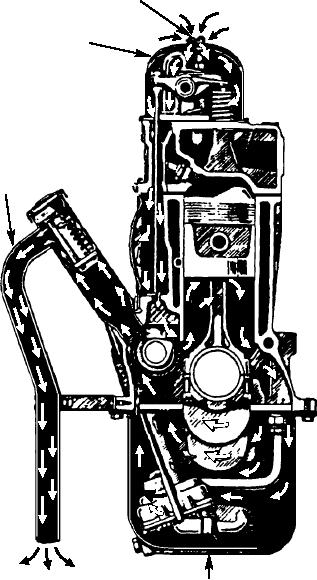

depends on a breather tube. Air flows past the open end

of the tube, evaporating the water and the gasoline and

removing the vapors from the crankcase. One end of

the breather tube opens into the crankcase above the oil

level. The other end extends down under the vehicle,

where there is sufficient airflow to create a low

pressure at the open end of the tube (fig. 5-21). The

pressure differential between the crankcase and the

open end of the tube is sufficient to force any vapors out

of the crankcase. Some breather tubes are placed so

ASf05021

VA P O R

that the cooling fan will increase the flow of air passing

CRANKCASE

over them, increasing their ventilating abilities.

Figure 5-21.--Crankshaft breather tube.

In the positive method, air is drawn through the

engine by an intake manifold vacuum; or, in other

Oil and Filter Change

words, the intake manifold vacuum draws air through

Whenever the engine oil feels gritty when

the crankcase to sweep vapors out of it (fig. 5-22).

rubbed between your fingers or has no body, it has

After picking up these vapors as it circulates through

lost its lubricating qualities and should be changed.

the crankcase, the air is forced upward and out of the

In any case, oil and filter changes are made in

engine through an opening in the valve cover, and it is

accordance with periodic maintenance (PM)

then drawn through a tube connected to the intake

schedules. On most of your equipment, the grade

manifold.

and quantity of the oil to be used can be found on the

To promote vaporization of volatile impurities and

MRC or in the technical manual. The oil should be

their removal from the crankcase, the operating

changed more frequently in cold weather and in

temperature of the engine should be at least 140F.

vehicles operated under dusty or other very

unfavorable conditions. Your chief or leading petty

LUBRICATION SYSTEM MAINTENANCE

officer will give you specific directions about oil

changes on such vehicles.

Lubrication s y s t e m m a i n t e n a n c e n o r m a l l y

consists of changing the oil and filters. Occasionally

Drain the oil only after the engine has been run

you might be required to perform such maintenance

and is warmed up. This warm-up period will thin the

tasks as replacing lines and fittings, servicing the oil

oil and stir up the sludge and foreign matter in the oil

pump and relief valve, and flushing the system.

pan. Cold oil is thick and will not drain readily, and

5-21