of paper or a composition of paper and other materials,

FLOATING STRAINER.--The floating strainer

and must be replaced periodically.

has a sealed air chamber, is hinged to the oil pump inlet,

and floats just below the top of the oil. As the oil level

FULL FLOW FILTERS.--Full flow filters (fig.

changes, the floating intake will rise or fall

5-15) are designed to filter the full oil output of the

accordingly. Thus, all oil taken into the pump comes

pump. This type of filter strains all of the oil before it is

from the surface. This prevents the pump from

distributed to the engine.

drawing oil from the bottom of the oil pan, where dirt,

With the full flow type filter, a relief or bypass

water, and sludge are likely to collect. The strainer

valve must be provided to allow the oil to flow around

screen is held to the float by a holding clip, and the up

the filter in the event the filter becomes clogged. This

or down movement of the float is limited by stops.

valve opens when the back pressure caused by

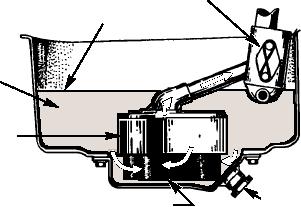

FIXED STRAINER.--The fixed strainer is

clogging becomes greater than the tension of the valve

simply an inverted funnel-like device, as shown in

spring. The engine is thus assured an adequate supply

figure 5-14, placed about 1/2 inch to 1 inch from the

of oil in case of filter failure. The bypass valve is

incorporated in the filter assembly or located in the

bottom of the oil pan. Thus, any sludge or dirt

engine block near the filter.

accumulation in the bottom of the pan is prevented

from circulating through the system. The assembly is

PARTIAL FLOW FILTERS.--Partial flow

attached solidly to the oil pump in a fixed position.

filters (fig. 5-16) strain only a small amount of the oil

being circulated by the pump. The oil from the main oil

Oil Filters

gallery enters the filter and flows through the filter

element. It then passes into the metal perforated

The oil cleaner, or filter, is placed in the oil line

collector in the center of the filter. The filtered oil then

beyond the pump and is usually mounted on the engine

flows out the outlet, which is restricted to prevent loss

in an accessible location. The average automotive

of pressure. After passing through the restriction, the

engine uses a single filter while larger engines,

oil either returns to the crankcase directly or by way of

especially diesel, use banks of two or more filters.

the timing gears, rocker arms, or other parts needing

The filter cleans the oil and removes most of the

lubrication. Where the return oil is used for lubricating

such parts, a bypass valve must be used to assure

impurities that were picked up by the oil as it circulated

circulation in the event the filter becomes clogged. A

through the engine. The filter is connected so that the

drain plug is usually incorporated in the bottom of the

oil passes through it each time the oil is circulated

filter case for sludge removal.

through the engine. Some oil filters have washable

filter elements and some have replaceable elements or

Oil Level Gauge

cartridges, while still others require replacement of the

entire assembly.

The oil level gauge, known also as a dipstick, is

The elements themselves may be either metallic or

usually of the bayonet type. It consists of a long rod or

nonmetallic. The metallic elements are made of

blade that extends into the oil pan. It is marked to show

bronze and are more or less permanent, since they are

EMPTY, LOW, and FULL, or sometimes just LOW

washable. Nonmetallic filter elements are composed

and FULL or FULL and ADD. Readings are taken by

OIL PUMP

OIL LEVEL

LOWER

OIL

INLET

SHIELD

DRAIN

OIL INLET SCREEN

ASf05014

PLUG

Figure 5-14.--Fixed oil strainer.

5-18