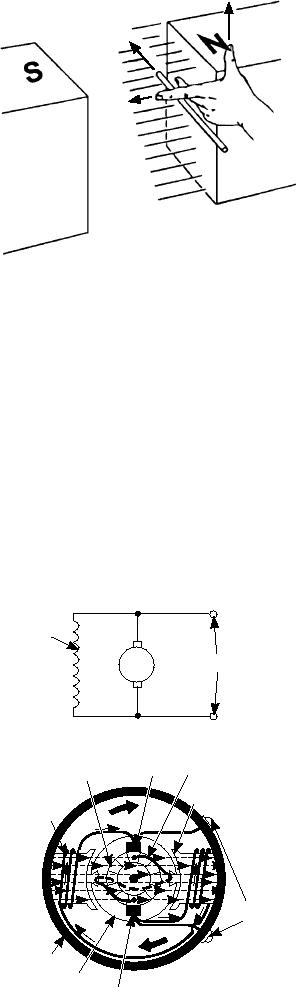

MOTION OF

connected to each other and to the commutator

CONDUCTOR

segments in such a way that the voltage impulses

CURRENT

overlap and produce a steady output voltage. This may

be compared to the overlapping of power impulses in an

automobile engine.

The armature core (fig. 6-14) on which the

armature windings or coils are mounted is made of

laminated soft iron. The core is laminated to reduce

eddy currents, and is made of soft iron for permeability.

The purpose of the field windings (field core) (fig.

6-14) is to increase the strength of the magnetic field so

more current will be induced in the armature windings

as the armature rotates. In most generators the field

ASf06013

windings are connected in parallel with the armature

Figure 6-13.--Left-hand rule for generators.

winding (that is, across the brushes); this arrangement

trated in figure 6-13, is applied as follows: Extended the

is called a shunt-field winding. Figure 6-14 represents a

left hand so the THUMB points in the direction of

shunt-wound generator with only one armature coil.

conductor movement (side of armature coil), and the

About 8 to 12 percent of the total current generated by

FOREFINGER points in the direction of magnetic flux

the armature is shunted through the field coils for produc-

(north to south). By pointing the MIDDLE FINGER 90

ing the magnetic field under normal load conditions.

degrees from the forefinger, it will point in the direction

Dc generators (figs. 6-15 and 6-16) consist of four

of current flow within the conductor.

main subassemblies or components: the frame and field

The simple generator circuit shown earlier in figure

assembly, the armature, the commutator end head

6-12 was for explanation purposes only. The output of

assembly, and the drive end head. The frame and field

that generator would be a very low dc voltage. In

assembly consists of the pole shoe, the field coils, and

reality, a generator must have several loops or turns of

the frame, which supports the remaining main

wire in each armature coil for sufficient voltage to be

components of the generator. The field coils supply the

induced into the coil (fig. 6-14). Likewise, the armature

magnetic field, which is necessary to generate

must have several coils distributed evenly around the

electricity. The pole shoes concentrate the magnetic

armature core. The coils or armature windings are

lines of flux of the field coils and hold the field coils in

place. The armature consists of a laminated iron core

fixed to a shaft and the copper windings, which are

SHUNT

FIELD

wound in slots in the core. The ends of these windings

GENERATOR

ARM.

are connected to the commutator, which consists of a

TERMINALS

number of copper segments that are insulated from

each other and from the core and shaft.

The commutator end head is a cast-iron plate that

closes one end of the frame and supports one of the

BRUSH

armature bearings. The commutator end head also

COMMUTATOR

ARMATURE

COIL

supports the brush holders and brushes that contact the

FIELD POLE

SHUNT

commutator to carry the electricity from the rotating

FIELD

WINDING

armature. The drive end head closes the drive end of the

frame and also supports a bearing for the armature

shaft.

Dc generators vary in design because of the

GENERATION

TERMINALS

different electrical and mechanical characteristics

desired for particular installations. The size, type of

mounting, type of drive, or the voltage and current

FRAME

ARMATURE

output differ, but all dc generators include the four

BRUSH

ASf06014

components just described.

Figure 6-14.--A shunt-wound generator.

6-16