INSTALLING

TOOL

INSTALLING

TOOL

DIODE TOOL

(FOR SUPPORT)

ASf06031

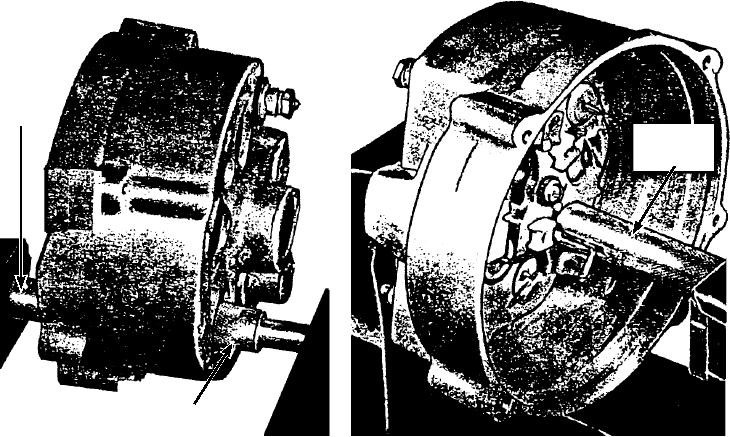

Figure 6-31.--Installing diodes.

When you install brushes, exercise care to

The bearing in the slip ring end frame assembly

must be replaced if its supply of grease is exhausted.

prevent chipping or other damage to them.

You should not attempt to relubricate and reuse a

It is not necessary to polarize the alternator

bearing in this condition.

system.

To replace a bearing, press the old one out of the

When you solder, use 60/40 rosin core. NEVER

slip ring end frame by using a tube or collar the same

use acid core; it is corrosive and can lead to further

diameter as the outside of the bearing. Press from the

damage.

outside while you support the inside with a hollow

cylinder to prevent distortion and breakage of the slip

Brushes and brush springs must be set in the

ring end frame. Install the new bearing by placing a flat

brush holder before assembly. They can be held in

plate over the bearing and pressing it in from the

position by a retaining pin or a stiff wire inserted

outside until the bearing is flush with the outside of the

through the hole provided in the slip ring end plate. Be

slip ring end frame. Support the inside with a hollow

sure to remove the pin after assembly.

cylinder to prevent distortion and breakage of the slip

Q6-12.

At what specific value will an alternator limit

ring end frame.

its current output?

Reassembly

1.

At 100% of its rated output

2.

At 110% of its rated output

Reassembly is essentially the reverse of the

3.

At 125% of its rated output

disassembly procedures given in the preceding section.

4.

At 130% of its rated output

However, there are a few points to remember.

Q6-13.

How many diodes does an automotive

When you assemble the drive belt pulley to the

alternator have?

rotor shaft, secure the rotor in a vise only tight enough

1.

Three

to tighten the nut to the torque specified by the

2.

Four

manufacturer.

3.

Five

Ensure that the bearing areas of the rotor shaft

4.

Six

are free of dirt or grime.

6-25