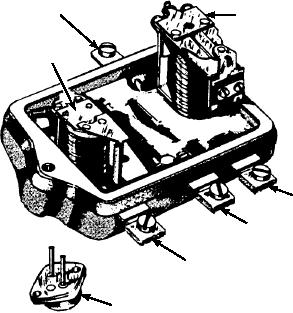

IGNITION

winding. The increased magnetism created by the

SWITCH

FIELD

TERMINAL

higher voltage across the winding causes the lower

RELAY

contacts to separate. Field current then flows through a

VOLTAGE

resistor, resulting in reduced field current. This reduced

REGULATOR

field current causes the alternator voltage to decrease,

which decreases the magnetic pull of the voltage

regulator shunt winding. The spring causes the contacts

to close, and the cycle then repeats many times per

second to limit the generator voltage to a preset value.

As the alternator speed increases even further, the

"F2"

resistor connected across the contacts is not of

TERMINAL

sufficiently high value to maintain voltage control on

"F1"

TERMINAL

the series (lower) contacts. Therefore, the voltage

BATTERY

increases slightly, causing the upper or shorting

TERMINAL

contacts to close. When this happens, the alternator

field winding is shorted and no current passes through

TRANSISTOR

(UNDER SIDE)

the winding. With no current in the field winding, the

ASf06036

alternator voltage decreases, which also decreases the

Figure 6-36.--Semitransistorized regulator.

magnetism in the shunt winding. The upper or shorting

contacts open. With these contacts open, field current

battery. Current passing through the field relay winding

flows through the resistor and the field winding. As the

creates magnetism that attracts the armature to the core,

voltage increases, the contacts close.

This cycle then repeats itself many times per

field winding F2 to the battery. The field circuit is

second to limit the alternator voltage to a preset value

completed to ground through the emitter-collector of

during high speeds. The regulator controls the

the transistor, the emitter-base of the transistor, and the

alternator output voltage throughout it s operating

voltage regulator contact points, which are normally

speed range.

held closed by the helical spring.

When the field relay contacts close, the two

SEMITRANSISTORIZED, TWO-UNIT,

windings on the voltage regulator are also connected

VIBRATING-CONTACT REGULATOR

across the battery. The resulting magnetism is not

strong enough, however, to overcome the adjusted

In the semitransistorized type of regulator, a single

tension of the helical spring, and causes the voltage

transistor works with a conventional voltage regulator

regulator contacts to open. The alternator field circuit

unit that contains a vibrating-contact point to maintain

is, therefore, completed to ground as soon as the

the alternator voltage at a preset level. The rotor current

ignition switch is closed.

passes through the emitter-collector of the transistor.

The rotor current is turned on and off by opening and

The alternator field windings carry full field

closing the emitter-base circuit through the regulator

current, producing a dc voltage at the BAT terminal on

contact points. In this arrangement, current passing

the alternator when it is in operation. When the

through the contact points is greatly reduced. The

alternator speed increases, the voltage increases. This

service life of this regulator is longer than that of a

voltage is impressed across the two windings on the

conventional vibrating-contact regulator.

voltage regulator unit. When the voltage reaches the

value at which the magnetism created by both windings

NOTE: For a complete and detailed explanation of

overcomes the spring tension, the armature is attracted

transistors and transistor theory, refer to NEETS,

toward the core and the contact points separate.

Module 7.

With the voltage regulator contact points open,

An example of this type of regulator is the

there is no emitter-base current, and consequently no

four-terminal unit shown in figure 6-36. It consists of a

emitter-collector current. The alternator field current,

field relay, a transistor, and a voltage regulator relay.

therefore, is turned off when the voltage regulator

When the ignition switch is closed (fig. 6-37), the

contacts are open. With no field current, the generated

winding on the field relay is connected across the

voltage immediately decreases. This smaller voltage

6-30