not heat the gauge blade sufficiently to bend it, and the

resistance in the sending unit. When the float reaches

blade holds the pointer at the empty reading.

the bottom, the sending unit presents a near zero

resistance. This provides a maximum current flow

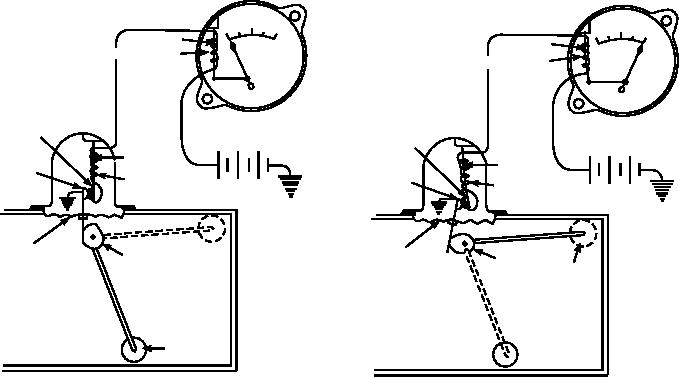

When the tank is full, the float is at the top and the

through the limiting coil and little through the operating

cam takes the position shown in view B of figure 6-76.

coil. The limiting coil draws the pointer to the totally

In this position, the cam pushes the grounded contact

empty position.

against the insulated bimetal contact, bending the

bimetal blade in the sending unit. Since the bimetal is

This type of gauge consumes very little current,

then under a strain, the current must flow longer to bend

about one-eighth of an ampere. Since the operation of

it sufficiently to open the contacts. The longer flow of

this gauge depends on the difference in the magnetic

current causes a bending of the bimetal blade in the

effect between two coils, variations in the battery

gauge unit, pushing the pointer over to the full position.

voltage will not cause an error in the gauge reading.

The contacts open and close fast enough to give a

THERMOSTATIC FUEL GAUGE.--The ther-

steady reading by the pointer. The maximum current

mostatic electrical fuel gauge has bimetal blades in the

requirement for a full reading is less than one-fourth

gauge and the sending unit. This type of gauge may also

ampere. This type of gauge is not affected by variations

be used as a temperature or oil pressure gauge by using

of battery voltage, and is compensated for outside air

changes in temperature or pressure to operate the

temperature variations.

movable grounded contact in the sending unit.

When the tank is empty and the float is down, as

Oil Pressure Gauge

shown in view A of figure 6-76, the two contacts in the

sending unit are just touching. Current flows through

The oil pressure gauge indicates the oil pressure in

the resistance heater wires of both gauge and sending

the system. Usually, such gauges are mounted on the

units, causing the bimetal blades to bend. Bending of

instrument panel and are calibrated to read oil pressure

the bimetal blade in the sending unit separates the

in pounds per square inch.

contacts to break the circuit. The heater wire cools

BOURDON TUBE OIL PRESSURE

when the current stops flowing, and the bimetal blades

GAUGE.-- Bourdon tube oil pressure gauges are

return to their original position. Contact is again made,

actuated by the pressure of air trapped above the oil in a

and the cycle of operation is repeated approximately

very small copper tube connected from the gauge to the

every second. Opening and closing of the contacts

lubricating system. Air pressure in the connecting tube

produces an intermittent flow of current, which does

BIMETAL

BIMETAL

HEATER WIRE

HEATER WIRE

GAUGE

INSULATED

GAUGE

INSULATED

CONTACT

CONTACT

BIMETAL

GROUNDED

BIMETAL

GROUNDED

CONTACT

HEATER WIRE

CONTACT

HEATER WIRE

DIAPHRAGM

DIAPHRAGM

CAM

CAM

FLOAT

SENDING UNIT

SENDING UNIT

FLOAT

A.

B.

O P E R AT I O N W I T H TA N K E M P T Y

O P E R AT I O N W I T H TA N K F U L L

ASf06076

Figure 6-76.--Thermostatic fuel gauge circuit.

6-63