rather than a gauge indicating system. The warning

temperature and the gas flows through the capillary, a

light is usually controlled by switches that may be

very small tube connecting the bulb to the gauge. The

operated by pressure, temperature, or mechanical

greater the heat, the more vapor is given off and the

linkage. You will encounter vehicles that use either a

greater the pressure; thus, higher temperature is

warning light system or a combination of warning light

indicated on the gauge.

and gauge systems.

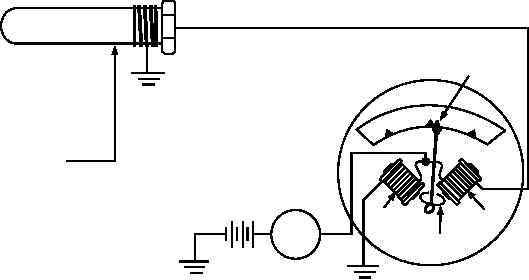

ELECTRICAL TEMPERATURE GAUGE.--

NOTE: To provide a means of testing the warning

The electrical temperature gauge (fig. 6-79) functions

lights, they are usually wired so that they illuminate

on much the same principle as the balancing coil fuel

when the ignition switch is placed in the starting

gauge and oil pressure gauge.

position.

The temperature gauge consists of two coils at right

angles to each other with an armature at the intersection

TEMPERATURE LIGHT.--Most late model

of the coil axes. Connected to the armature is a pointer.

vehicles use an engine temperature warning light

The sending unit is a resistor whose resistance varies

(located on the instrument panel) in place of the

inversely with the temperature of the engine. When the

conventional engine temperature gauge. The warning

engine temperature is high, the sender's resistance is

light is wired in series with the ignition switch and the

low; when the temperature is low, the resistance is high.

engine temperature sending unit. The sending unit

On the low-temperature side of the gauge unit, the coil

provides ground for the warning lights when its

is connected directly across the battery. Thus, there

contacts are closed. There are two systems for the

exists a constant magnetic strength in that coil, which

temperature warning lights that are commonly used.

attracts the armature and pointer to the low-temperature

One of the systems contains a cold light (green) and

side. However, the coil on the high-temperature side is

a hot light (red). These lights are controlled by the

connected in series with the resistance of the sending

engine temperature sending unit, which has two sets of

unit and across the battery. Since the sender's resistance

contacts, one set being normally closed for the cold

varies with temperature, the coil's magnetic strength

light and one set being normally open for the hot light.

varies. More current flows when the resistance is low

The contacts are mounted on bimetal strips, which

(high engine temperature), and so a stronger magnetic

cause them to open and close at predetermined

field is created. As engine temperature increases, the

temperatures. For example, when the engine is first

greater magnetic strength of the high-temperature coil

started, the cold light comes on until the engine reaches

attracts the armature and pointer to a point of balance

normal operating temperature. Then, the cold light

between the two sides. The scale is calibrated to the

switch contacts open and the light goes off. This lets the

pointer movement.

operator know that it is safe to apply load to the engine,

which is then at normal operating temperature.

Warning Lights

Likewise, if the engine overheats, the hot light switch

contacts close and the hot light comes on, warning the

Some automotive manufacturers prefer a warning

operator of the overheating condition.

light system that indicates certain operating conditions,

POINTER

ENGINE UNIT IS

180

IMMERSED IN

22

0

12

ENGINE COOLANT.

0

RESISTANCE OF

UNIT DECREASES

WITH HEAT

BATTERY

COIL

COIL

ARMATURE

IGNITION

DASH UNIT

ASf06079

SWITCH

Figure 6-79.--Electrical temperature gauge.

6-65