The other system mentioned operates on the same

principles but does not have a cold warning light. It has

the hot warning light and an engine temperature

1

_

sending unit with a single set of normally open

10

contacts. If the engine overheats, the contacts close and

turn on the hot warning light.

014375

OIL PRESSURE LIGHT.--The oil pressure

TOTAL HOURS

warning light installed on some vehicles is also located

on the instrument panel to indicate when the oil

pressure is very low. The warning light is wired in

series with the ignition switch. The oil pressure switch

is located on the automotive engine.

A

The oil pressure switch contains a diaphragm and a

0

set of contacts. When the ignition is turned on, the

1 HO

9

warning light should illuminate, because the light

1

UR

10 H

RS

circuit is energized through the closed contacts in the

100

HR

S

oil pressure switch. When the engine is started, built-up

8

2

oil pressure compresses the diaphragm, opening the

contacts, and thereby opening the circuit and causing

the warning light to go out. The warning light is usually

red and indicates a bright "Oil" on the instrument panel.

7

3

ALTERNATOR LIGHT.--Some vehicles use an

alternator warning light mounted on the instrument

6

4

panel in place of the ammeter. The light indicates to the

5

operator when the alternator is not charging the battery.

B

The warning element is a panel-mounted window

(usually red) behind which is mounted a small light

0

bulb. The light comes on when the ignition is turned on

10 HO

9

1

U

RS

and the alternator is not charging. The circuit is

100

HR

S

1000

HR

completed from the ignition switch, through the light,

S

to a terminal on the indicator light relay.

8

2

When the engine is running, the alternator speed is

sufficient to provide a voltage higher than that of the

battery. The operating coil of the indicator light relay

7

3

will be energized, opening the circuit between the

indicator light and the battery.

6

4

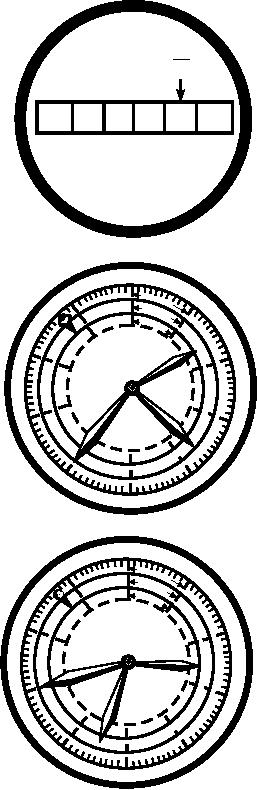

Hour Meter

5

C

Some support equipment requires servicing or

ASf06080

maintenance after operating a certain amount of time.

Figure 6-80.--Hour meters.

Hour meters (fig. 6-80) provide maintenance personnel

a means of determining the specific amount of time the

equipment has operated. With the information from the

electrically driven type records elapsed time (clock

hour meters and maintenance instructions, mainte-

hours). The mechanically driven type records time after

nance personnel can determine what maintenance is

a certain number of functions have taken place. For

required and when to perform it.

example, the hour meter may be designed to advance an

hour after the crankshaft of an engine has completed as

There are two types of hour meters commonly used

many revolutions as it normally would during an hour's

on support equipment. These are the electrically driven

operation.

(most common) and the mechanically driven types. The

6-66