5

1

2

4

3

6

8

7

9

10

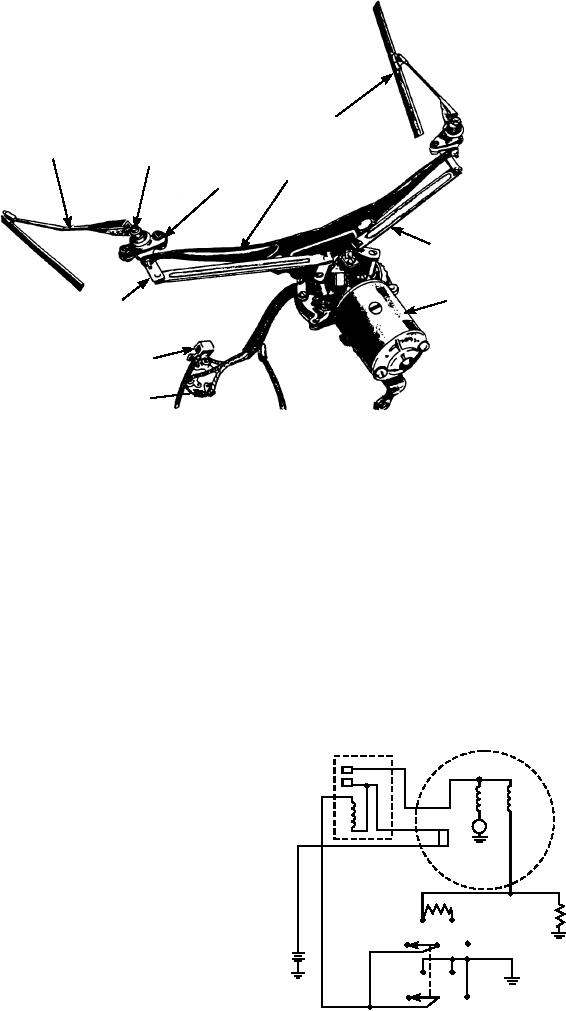

ASf06091

1. Wiper arm

3. Pivot cover

5. Wiper blade

7. Motor

9. Circuit breaker

2. Wiper arm nut

4. Mounting bracket

6. Linkage

8. Pivot

10. Wiper switch

Figure 6-91.--Electrically operated windshield wipers.

Whether or not the directional signal switch

Electrical windshield wipers (fig. 6-91) are usually

driven by shunt or compound wound motors. The

lever has returned to the neutral position after

wipers may be driven in three different speeds--slow,

completion of a turn.

medium, and fast.

Whether the system is operating properly or

To obtain satisfactory operation from electrical

improperly.

windshield wipers, it is essential that the motor,

When the signal switch lever is moved in one

linkage, and drive pivots operate freely. Otherwise

direction or the other, a circuit is completed between

operation may be noisy or complete failure may result.

the battery and the proper indicating lights. The

A modern three-speed windshield wiper schematic

connections are completed through a flasher, a device

is shown in figure 6-92. The system contains a

that opens and closes the circuit at proper intervals,

providing a flashing signal. The flashing action is a

result of heating a thermostatic element within the

MOTOR

SERIES

flasher. The wiring circuit of a representative

FIELD

stop-directional light signal system indicating a right

SHUNT

turn with the brakes applied is shown in figure 6-90.

FIELD

M

WINDSHIELD WIPERS

CIRCUIT

BREAKER

Windshield wipers usually consist of a metal strip

with a rubber insert attached to a rod that swings in an

R2

LO

M

R1

arc across the windshield. The necessary mechanical

linkage is driven by an electric motor. Windshield

HI

OFF

wipers are not a common support equipment accessory.

LO

M

However, they must be installed when the operator is

OFF

HI

situated in an enclosure. Examples are the crash cranes,

ASf06092

some types of fire trucks, and enclosure-equipped tow

Figure 6-92.--Schematic diagram of a three-speed windshield

tractors.

wiper.

6-73