The engine starting circuit

ineffective because of the varying electrical loads. For

these reasons all MEPPs use some type of automatic

The vehicle propulsion circuit

governor. The NC-2A power plant uses two electronic

governors--the drive control module assembly and the

The dc power control and distribution circuit

engine governor assembly.

The ac power control and distribution circuit

Control of the engine speed is accomplished by an

electric torque motor that adjusts the fuel flow to the

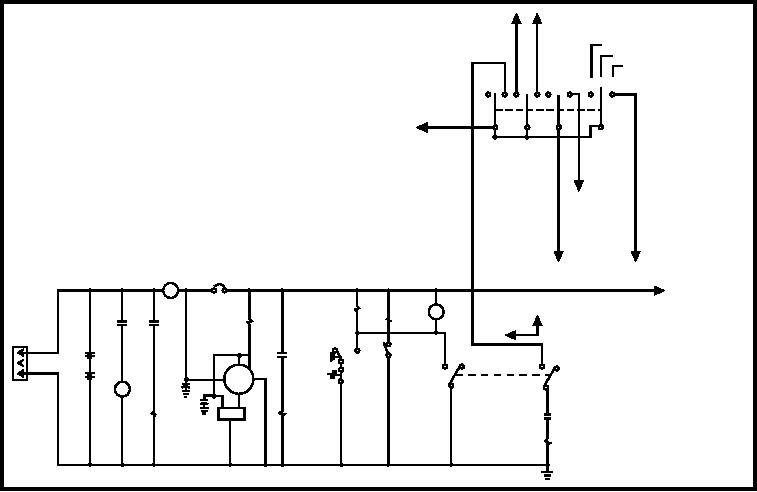

ENGINE STARTING CIRCUIT.--Figure 7-40

engine. The movement of the torque motor shaft is

is a simplified schematic of the NC-2A starting circuit,

controlled by the selected governor assembly. The

and figure 7-41 is a picture of the NC-2A control panel.

operation of the NC-2A is selected by positioning the

mode selector switch. With the mode selector switch in

Prior to starting the engine, MASTER SWITCH

the START/DRIVE position, the drive module

CB4 (fig. 7-40) must be closed, start cutout relay K21

assembly controls the torque motor and the speed of

must be energized (closing contacts B1 and B2), and

the dc generator.

START/DRIVE-SERVICE POWER switch S29 must

The engine governor assembly takes control of the

be in the START/DRIVE position.

torque motor when the mode selector switch is turned

Holding ENGINE START switch S14 in the start

to the output power position. The engine governor

position energizes auxiliary start relay K20. Start

solenoid L1 is now energized through the closed

maintaining it at 400 hertz, plus or minus 10 hertz.

contacts of relay K20 and in turn cranking motor B3 is

energized through the closed contacts of solenoid L1.

System Operation

Fuel shutoff solenoid L3 is also energized permitting

free flow of fuel to the engine and is held energized

The NC-2A system is broken down into four major

during unit operation through water temperature

interrelated circuits for ease of explanation. Those

switch S11 and engine oil pressure switch S15.

circuits are:

TO GOVERNOR

INTERFACE MODULE

SERVICE POWER

SERVICE BOOST

START/DRIVE

CBA

S29

1

34

67

9

10

12

24 VDC

2

5

8

11

TO DC POWER

CONTROL &

DISTRIBUTION

CIRCUIT

TO PROPULSION CIRCUIT

TO DC VOLTAGE

CB4

REGULATOR

M4

L3

OFF

M7

X1

A1

X1

A1

K19

K21

L1

K20

X2

X2

A2

START

NO

S15

A1

S19

+

+

K19

BT1

NO

A2

1

4

3

6

C

AUX

G3

-

BT2

B+ GRD

S11

S14

-

C1

2

J5

5

B3

F

0.1UF

200V

RD GRN

B1

V

F BLK

L1

L2

K21

C2

B2

VR3

0.1 UF

X1

200V

K20

X2

ASf07040

Figure 7-40.--Engine starting circuit.

7-33