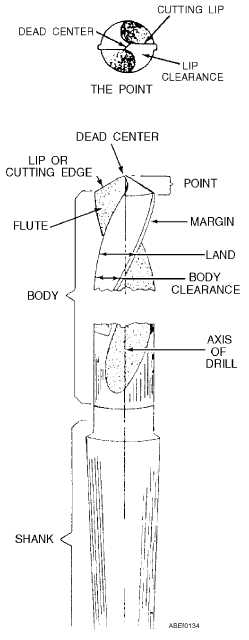

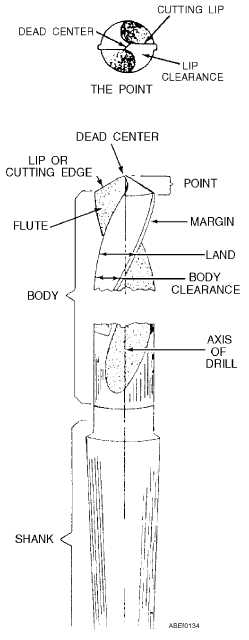

The principal parts of a twist drill are the body, the

shank, and the point (fig. 1-24). The dead center of a

drill is the sharp edge at the extreme tip end of the drill.

It is formed by the intersection of the cone-shaped

surfaces of the point and should always be the exact

center of the axis of the drill. The point of the drill

should not be confused with the dead center. The point

is the entire cone-shaped surface at the end of the drill.

The lip or cutting edge of a drill is that part of the

point that actually cuts away the metal when drilling a

hole. It is ordinarily as sharp as the edge of a knife.

There is a cutting edge for each flute of the drill.

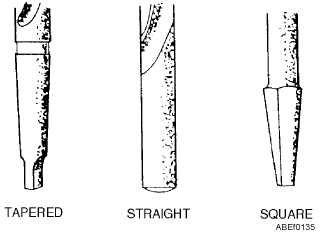

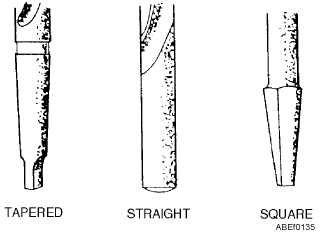

The shank is the part of the drill that fits into the

socket, spindle, or chuck of the drill press. Several

types exist (fig. 1-25).

The maintenance of twist drills and more about

how to use them on specific jobs are discussed later.

REVIEW QUESTIONS

Q7.

Identify the different types of metal-cutting

tools.

Q8.

What are hawks-bill snips used for?

Q9.

What are hacksaws used for?

Q10.

What are taps and dies used for?

WRENCHES

LEARNING OBJECTIVES: Identify the

different types of wrenches. Describe the uses

of different types of wrenches. List the safety

precautions that apply to wrenches.

A wrench is a basic tool that is used to exert a

twisting force on bolt heads, nuts, studs, and pipes. The

special wrenches designed to do certain jobs are, in

most cases, variations of the basic wrenches that are

described in this section.

The best wrenches are made of chrome vanadium

steel. Wrenches made of this material are lightweight

and almost unbreakable. This is an expensive material,

however, so the most common wrenches found in the

Navy are made of forged carbon steel or molybdenum

steel. These latter materials make good wrenches, but

they are generally built a little heavier and bulkier to

achieve the same degree of strength as chrome

vanadium steel.

1-18

Figure 1-24.—Twist drill nomenclature.

Figure 1-25.—Representative shanks.