tensioner sheave assembly. The sheave assembly

mounted on the tensioner frame guides the cables as

they pass from the sheave and adapter assembly to the

clevis assembly. The lead sheave assemblies guide the

cables between the retraction engine and the grab.

BRIDLE TENSIONING SYSTEM (DECK)

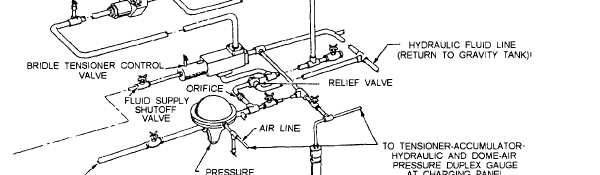

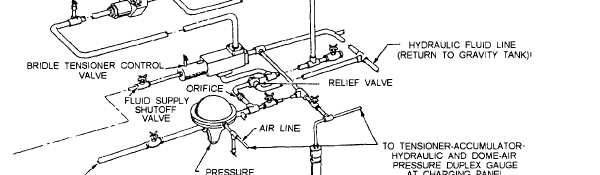

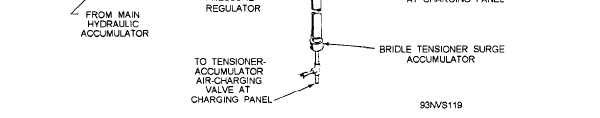

The bridle tensioning system (fig. 4-57) consists of

a bridle tensioner

cylinder,

control

valves,

pressure-reducing valves, accumulators, limit switches,

and associated valves and piping.

NOTE

The Mk 2 nose gear launch unit is an

integral part of the bridle tensioning system. Its

description and operation is discussed later in

this manual.

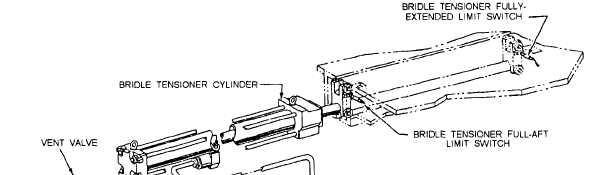

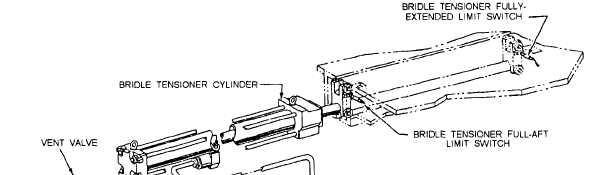

The bridle tensioner cylinder assembly (fig. 4-58)

is mounted in the nose-gear-launch-unit deck housing,

aft of the catapult track. The purpose of the tensioner

cylinder is to exert force on the catapult shuttle, via the

shuttle grab assembly, to tension the aircraft launching

hardware prior to launching.

The piston rod extends into the catapult track, and

a ram support on the forward end of the rod is equipped

with rollers that bear on the catapult track surfaces. A

port on the forward end of the cylinder is pressurized at

all times the bridle tensioner pressure regulator valve is

charged. Fluid flow to the port on the after end of the

cylinder is controlled by the bridle tensioner control

valve.

When the aircraft is tensioned, the bridle tensioner

control valve (fig. 4-57) directs fluid from the pressure

regulator to the aft port of the bridle tensioner cylinder.

This fluid pressure acting on the large surface of the aft

end of the piston causes the grab and shuttle to move

forward. When the control valve is shifted to vent the

aft end of the cylinder to gravity, the constant pressure

on the forward side of the piston moves the piston back

to its FULLY AFT position.

Figure 4-57.—Bridle tensioning system.

4-45