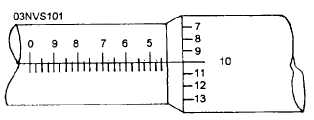

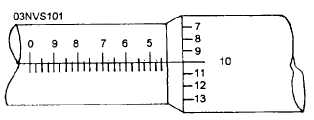

Figure 2-30.—Depth micrometer sleeve and thimble scales.

used gives you the total depth of the hole, rcccss, or

groove that was measured.

SELECTING THE PROPER

MICROMETER

The types of micrometers commonly used are made

so that the longest movement that the micrometer

spindle or rod can make is 1 inch. This movement is

called the range; for example, a 2-inch micrometer has

a range of from 1 inch to 2 inches, and can only

measure work with a thickness or diameter within that

range. Therefore, it is necessary to first determine the

approximate size, to the nearest inch, of the work to be

measured and then select the proper size micrometer.

The size of a micrometer indicates the size of the

largest work it can measure.

CARE OF MICROMETERS

Keep micrometers clean and lightly oiled. Make

sure they are always stored in a case or box when not

in use, to protect them from damage. Never clean any

part of a micrometer with emery cloth or other abrasive.

The measuring tools that have been described in this

chapter are the ones that you, as an ABE, will routinely

usc while performing your assigned duties. You may,

however, occasionally be required to use other less

commonly used measuring tools. Some of these arc the

dial indicator, telescopic (snap) gauge, the vernier

caliper, or screw thread gauge. The description of these

tools and instructions for their use can be found in the

training manual Use and Care of Hand Tools and

Measuring Tools, NAVEDTRA 12085.

INVENTORY AND ACCOUNTABILITY

All measuring tools will be marked in some

manner, etched, stenciled, etc., to comply with standard

inventory instructions. These standard instructions may

be found in OPNAVINST 4790.15

Some measuring tools such as tapes and calipers

may be part of a specific tool box inventory. Other

precision measuring instruments such as micrometers,

snap gauges and vernier calipers will normally be

maintained in the division’s central tool room.

Regardless of the tool’s permanent location, it is always

the user’s responsibility to maintain, care for and use

the tool properly.

Damage, loss, or an improperly working tool should

be reported immediately. Loss of a tool becomes

especially critical when working on or around the

catapult or arresting gear machinery. The tool may be

“lost” in the machinery and, if not found, may cause

catastrophic damage to the equipment and serious injury

to personnel. Always double-check the inventory

ensuring every tool is accounted for

upon job

completion. The proper tools will help you maintain

your equipment but only if you maintain your tools

properly

SUMMARY

This chapter has introduced you to some of the

most often used measuring tools and the techniques for

using them. Selecting the proper tool; using and

maintaining the various tools; and inventorying the

tools have all been discussed.

By thoroughly

understanding and comprehending this chapter, you, as

an ABE, will be able to perform your daily duties more

efficiently and safely.

2-12