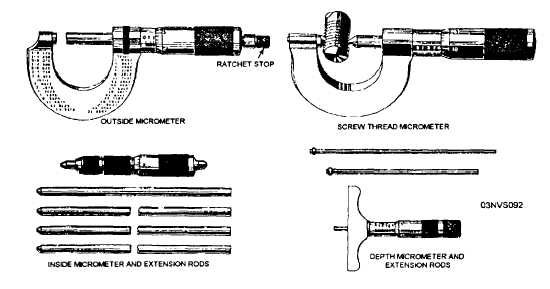

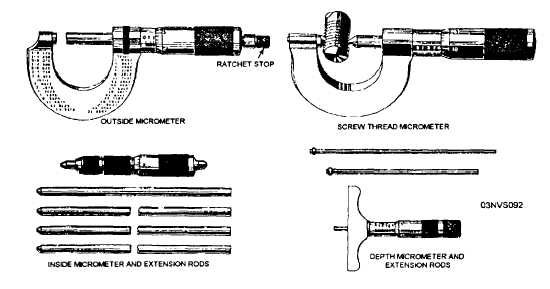

Figure 2-21.—Common types of micrometers.

the point of contact of the two lower caliper legs. In

this figure the inside caliper is being adjusted to the

size of the outside caliper. As careful measurements

with calipers depend on one’s sense of touch, which is

spoken of as “feel,” calipers are best held lightly. When

you notice a slight drag, the caliper is at the proper

setting.

CARE

Keep calipers clean and lightly oiled, but do not

over oil the joint of firm-joint calipers or you may have

difficulty in keeping them tight. Do not throw them

around or use them for screwdrivers or pry bars. Even

a slight force may spring the legs of a caliper so that

other measurements made with it are never accurate.

Remember, calipers are measuring instruments and must

be used only for the purpose for which they are

intended.

PRECISION MEASURING EQUIPMENT

In much wider use by ABEs than even common

calipers are the various types of micrometer calipers. As

was stated earlier, you can use micrometer calipers to

take accurate measurements to the nearest one

ten-thousandth of an inch. However, in most

applications a

measurement to

the

nearest

one-thousandth of an inch is considered acceptable

accuracy. These measurements are expressed or written

as a decimal (0.0001, 0.001, 0.01), so you must know

how to read and write decimals.

TYPES OF MICROMETER CALIPERS

There are three types of micrometer calipers,

commonly called micrometers or simply mikes, used

throughout the Navy: the outside micrometer, including

the screw thread micrometer; the inside micrometer; and

the depth micrometer. (See fig. 2-21.) The outside

micrometer is used for measuring outside dimensions,

such as the outside diameter of a piece of round stock

or the thickness of a piece of flat stock. The screw

thread micrometer is used to determine the pitch

diameter of screws. The inside micrometer is used to

measure the inside diameter of a cylinder or hole. The

depth micrometer is used for measuring the depth of a

hole or recess.

Outside Micrometer

The nomenclature of an outside micrometer is

illustrated in figure 2-22.

The sleeve and thimble scales of a micrometer (fig.

2-23) have been enlarged and laid out for

demonstration. To understand these scales, you need to

know that the threaded section on the spindle, which

revolves, has 40 threads per inch. Therefore, every time

the thimble completes a revolution, the spindle

advances or recedes 1/40 inch, or 0.025 inch.

Note the horizontal line on the sleeve is divided

into 40 equal parts per inch. Every fourth graduation is

2-8