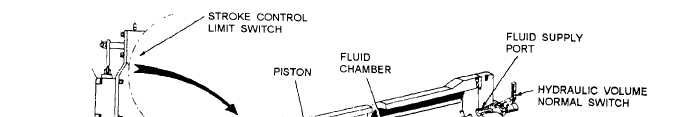

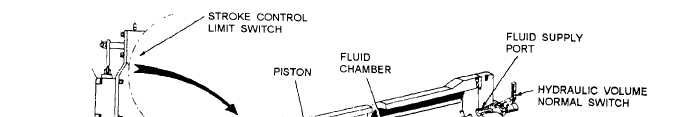

The pumps can also be manually operated through

the stroke-control switch, which is wired in series with

the tailrod switch. Both switches must be in the ON

position for the pumps to be placed onstroke. The

stroke-control switch is used to turn the pumps

offstroke before starting the pump-motor sets, so that

they may be started and operated for a few minutes

without a load.

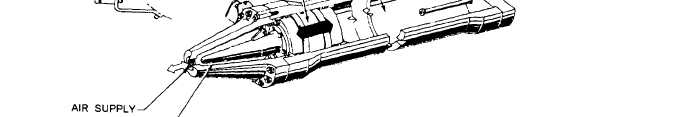

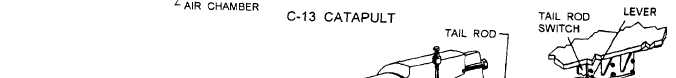

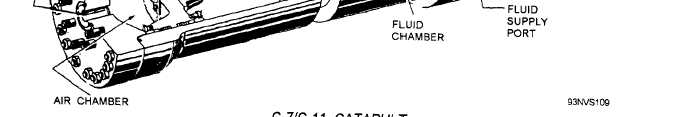

For C-13 catapults, automatic operation of the

pumps is accomplished through the action of a tapered

spear bolted to the air side of the air/oil separator

piston. As the piston is forced toward the air end of the

accumulator, the tapered spear comes into contact with

a lever and roller assembly

shaft located in the end

enters the cap, it causes

cap

the

attached to a horizontal

(fig. 4-47). As the spear

lever and shaft to rotate,

causing a cam on the end of the shaft to actuate the

stroke control limit switch, causing the pumps to go

offstroke. As the fluid is displaced to various

components of the catapult, air forces the piston away

from the actuator assembly, allowing the cam to rotate

off the switch and causing the pumps to kick onstroke

automatically. Manual operation is basically the same as

on the C-7/C-11 catapults.

NOTE

Always ensure that the stroke control

push button is in the OFF position prior to

turning on the pumps. The C-13 catapult also

incorporates a hydraulic volume normal switch

that performs the same function as on the

C-7/C-11 catapults.

4-37

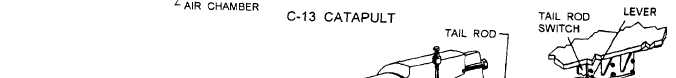

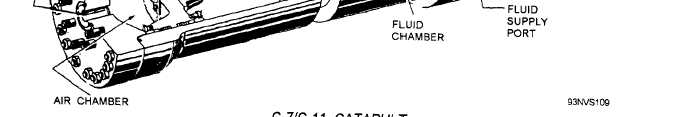

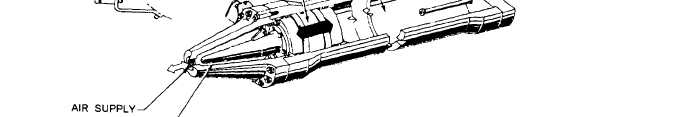

Figure 4-47.—Linear retraction engine accumula