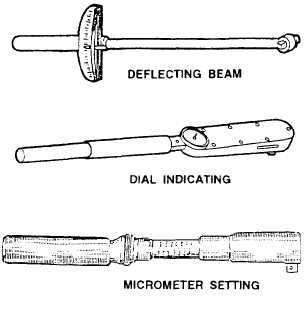

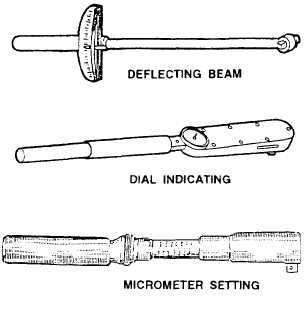

micrometer setting types (fig. 2-35). When using the

deflecting beam and the dial indicating torque

wrenches, the torque is read visually on a dial or scale

mounted on the handle of the wrench.

To use the micrometer setting type, unlock the

grip and adjust the handle to the desired setting on the

micrometer-type scale, then relock the grip. Install the

required socket or adapter to the square drive of the

handle. Place the wrench assembly on the nut or bolt

and pull in a clockwise direction with a smooth,

steady motion. (A fast or jerky motion will result in an

improperly torqued unit.) When the torque applied

reaches the torque value, indicated on the handle set-

ting, a signal mechanism will automatically issue an

audible click, and the handle will release or “break, ”

and move freely for a short distance. The release and

free travel are easily felt, so there is no doubt about

when the torquing process is complete.

Manufacturers’ and technical manuals generally

specify the amount of torque to be applied. To assure

getting the correct amount of torque on the fasteners,

it is important that you use the wrench properly ac-

cording to manufacturers’ instructions.

Use that torque wrench that will read about mid-

range for the amount of torque to be applied. BE

SURE THAT THE TORQUE WRENCH HAS BEEN

CALIBRATED BEFORE YOU USE IT. Remember,

too, that the accuracy of torque measuring depends a

lot on how the threads are cut and the cleanliness of

the threads. Make sure you inspect and clean the

Figure 2-35.—Torque wrenches.

threads. If the manufacturer specifies a thread lubri-

cant, it must be used to obtain the most accurate

torque reading. When using the deflecting beam or

dial indicating wrenches, hold the torque at the de-

sired value until the reading is steady.

Torque wrenches are delicate and expensive

tools. The following precautions should be observed

when using them:

1. When using the micrometer setting type, do not

move the setting handle below the lowest torque setting.

However, place it at its lowest setting before returning

it to storage.

2. Do not use the torque wrench to apply greater

amounts of torque than its rated capacity.

3. Do not use the torque wrench to break loose

bolts that have been previously tightened.

4. Do not drop the wrench. If dropped, the accu-

racy will be affected.

5. Do not apply a torque wrench to a nut that has

been tightened. Back off the nut one turn with a nontor-

que wrench and retighten to the correct torque with the

indicating torque wrench.

6. Calibration intervals have been established for

all torque tools used in the Navy. When a tool is cali-

brated by a qualified calibration activity at a shipyard,

tender, or repair ship, a label showing the next calibra-

tion due date is attached to the handle. This date should

be checked before a torque tool is used to ensure that it

is not overdue for calibration.

MICROMETERS

The type of micrometers commonly used are made

so the longest movement possible between the spindle

and the anvil is 1 inch. This movement is called the

range. For example, a 2-inch micrometer has a range

from 1 inch to 2 inches, and only measures work be-

tween 1 and 2 inches thick. Therefore, you must first

determine the approximate size, to the nearest inch, of

the piece to be measured and then select the proper size

micrometer. The size of a micrometer indicates the size

of the largest work it can measure.

Outside Micrometer

The nomenclature of an outside micrometer is

illustrated in figure 2-36.

2-24