forward to aft (or vice versa), when filling amidship

emergency tanks (on ships so equipped), and when

off-loading JP-5.

The common suction and discharge headers of

the transfer pumps are interconnected with the

suction and discharge headers of the service pumps.

This arrangement enables the service pumps to be

used as transfer pumps (normally for off-loading JP-

5). Be-cause of insufficient (static) head lift and the

low pumping capacity of the transfer pumps, they are

not normally used for transferring JP-5 off the ship.

The cross-connections between the respective suction

and discharge headers are fitted with a spectacle

flange or a line blind valve (blank side in), and a

cutout valve (normally locked closed).

Reclamation System

The reclamation system provides the capability

to reclaim JP-5 received from hose flushings, JP-5

tank stripping operations, and the initial flow during

a fueling at sea (FAS). The water and sediment

received from these operations are permitted to settle

out in the contaminated-JP-5 settling tanks. JP-5

drawn off by the designated JP-5 transfer pump is

discharged through the reclamation prefilter and

fiber/separator and then into JP-5 storage tanks.

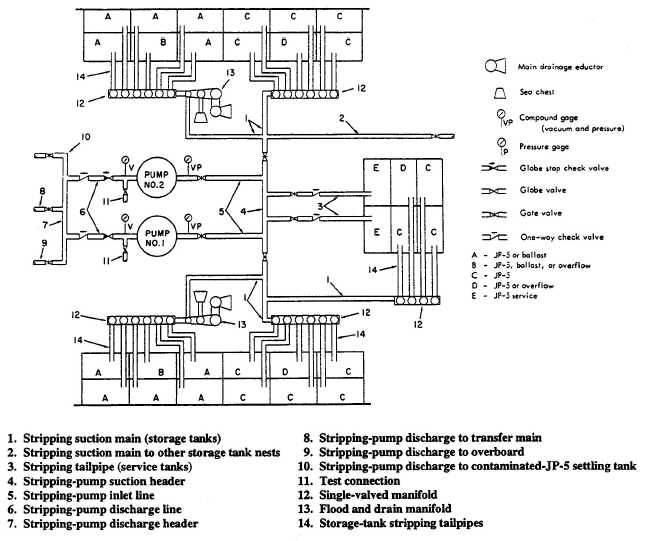

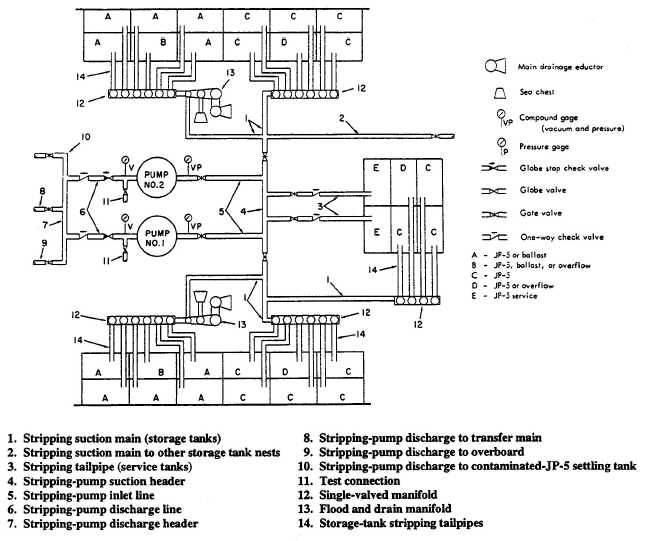

STRIPPING SYSTEM

There are two independent stripping systems in

each JP-5 pump room. One system uses motor-driven

pumps and is interconnected with all JP-5 tanks

(both storage and service). The other system uses

hand-operated pumps and is installed in service

tanks only. The systems we will describe here are the

typical setup for one pump room. Since they operate

independently, we will describe each separately.

Motor-Driven Stripping System

The motor-driven stripping system (fig. 4-3) con-

sists of two low-capacity pumps, manifolds, and

Figure 4-3.—Typical motor-driven stripping system.

4-5