Compressor Failures

Loose objects often enter an engine's compressor

either accidentally or through carelessness. Thousands

of dollars worth of damage to a compressor rotor can

result from pliers being left in the air intake, as shown

in figure 10-1. The nut and bolt holding the pliers

together came loose and went through the compressor,

causing the damage shown in the illustration. A simple

solution to the problem of tools drawn into an engine is

to check the tools against a tool checklist.

Internal mechanical failures, such as a compressor

blade breaking off, result in compressor efficiency loss.

These failures are difficult to detect. Broken blades and

vanes result in high exhaust gas temperatures or an

increase in compressor rpm due to loss of efficiency. Of

course, mechanical failures of compressor blades could

result in severe damage to the compressor, combustion

chamber, and the turbine as foreign object damage

(FOD).

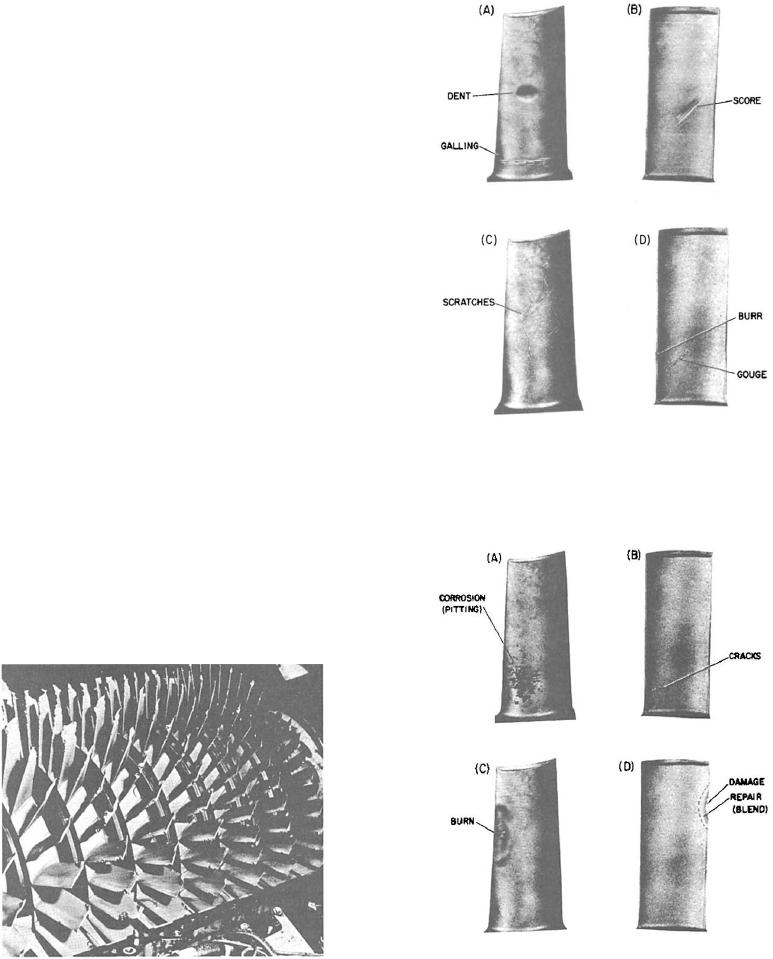

Compressor Blade Damage

and Repair

Figure 10-2.-(A) Blade showing dent and galling;

(B) blade showing a score; (C) blade showing

Defining and showing examples of damage may help

scratches; (D) blade showing gouge and burr.

you to recognize damage and make

Figure 10-3.-(A) Blade showing corrosion

(pitting); (B) blade showing cracks; (C) blade

Figure 10-1.-Compressor damage caused by

showing burn; (D) blade showing damage and

pliers passing through compressor.

repair (blend).

10-6