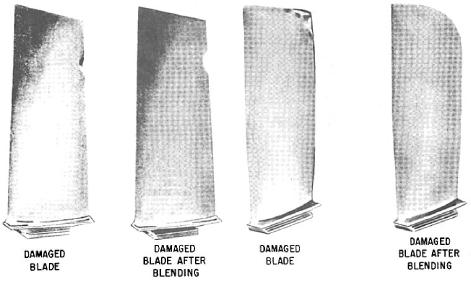

Figure 10-5.-Compressor blade repair.

compressor stator. The inspection and repair of air

as viewed from the front. Install blades in their

inlet guide vanes and swirl vanes on engines require

correct numbered position. Make sure new blades are

the use of a strong light. Attach this light to a rigid

correctly numbered for the blades they replace.

support to enable positioning in hard-to-reach areas.

NOTE: The blade part number follows a

Inspect all sections of both screen assemblies for

change designation number. Never take

breaks, rips, or holes. Screens may be tin-dipped to

this number as the moment weight

tighten up the wire mesh, provided the wires are not

code of the blade. The code letter i s

worn too thin. If the frame strip or lugs have

stamped adjacent to, but not following,

separated from the screen frames, rebrazing may be

the part number.

necessary.

Compressor Stator Vanes

Inspect guide and swirl vanes for looseness.

Inspect the outer edges of the guide vanes. Pay

particular attention to the point of con-tact between

Pitting or corrosion, if within the allowed

the guide and swirl vanes. Check for cracks and dents

tolerance, is not serious on the compressor stator

due to the impingement striking of foreign particles.

vanes of axial-flow engines. Do not attempt to repair

Also, inspect the edges of the swirl vanes. Inspect the

any vane by straightening, brazing, welding, or

downstream edge of the guide vanes very closely, as

soldering. Use crocus cloth, fine files, and stones to

cracks are more prevalent in this area. Cracks which

blend out damage. Remove a minimum of material,

branch in such a manner that a piece of metal could

and leave a surface finish comparable to that of a new

fall into the compressor are cause for rejection.

part. The purpose of this blending is to minimize

stresses, which concentrate at dents, scratches, and

Blending of hollow vanes on the concave and

cracks. Maximum blend out limit damage greater

convex surfaces, including the leading edge, is

than 50 percent of the stator assembly vanes requires

limited, Some small, shallow dents are acceptable.

assembly replacement. When vanes are damaged, to

The damage may be rounded or gradual contour type,

the maximum blend out limit in any 60-degree sector

but not a sharp or V-type. Do not allow any cracked

of one stage, replace the assembly. Send parts

or torn vane material to exist in the damaged area.

damaged beyond maximum repair limits to overhaul

for repair and replacement of vanes. The use of

Blend the trailing edge if one-third of the weld

prebored compressor vane and shroud assemblies

seam

remains

after

repairs.

See

permits the replacement of one-half of any low-

10-9