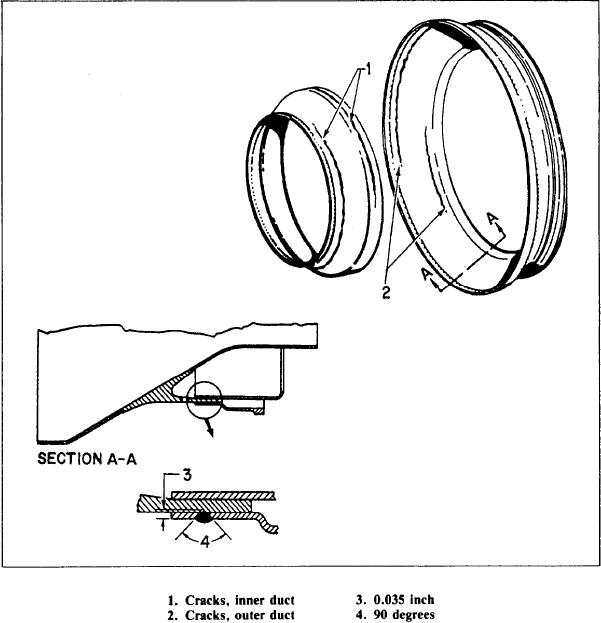

TURBINE SECTION REPAIRS

exceed 3 inches in length. Repair cracks more than

3 inches long and exceeding 75 percent of the

Inspect turbine sections and components

entire circumference of the duct by gas fusion

thoroughly because of the extreme heat en-

welding. When repairing a duct, use a silicone

countered in this section. Turbine sections can

carbide grinding wheel. Grind a 90-degree "V"

groove, 0.035-inch deep, for the entire length of

be replaced in whole or in part. The turbine rotor

is usually repaired by changing individual blades

the crack. It is permissible to remove some of the

or an individual rotor. It is not feasible to describe

parent material when grinding. Adequate depth

all of the damage conditions that may be found

is necessary to be sure that the grinder removes

in the turbine. If the damage is within prescribed

all material from the crack. Repairs must not

limits, but there is doubt about the rework, you

result in distortion or misfit of the parts at

should replace the turbine rotor or part.

assembly. File out any distorted hole, as a result

Some first-stage turbine blades are coated with

of welding, to restore it to the original configura-

a protective coating to prevent sulfidation. Alpak

tion. See figure 10-10 for an example of inner and

is normally used for coating these blades. Without

outer ducts repair limits.

Figure 10-10.-Combustion chamber inner and outer duct.

10-13