this coating, these blades are very susceptible to

by a rough or crusty appearance at the leading edge,

sulfidation.

on the concave side of the airfoil section, or on the

platform at the root of the air-foil. The rotor should be

Turbine Blade Sulfidation

replaced if there is evidence of splitting,

delamination, separating, flaking, or loss of material

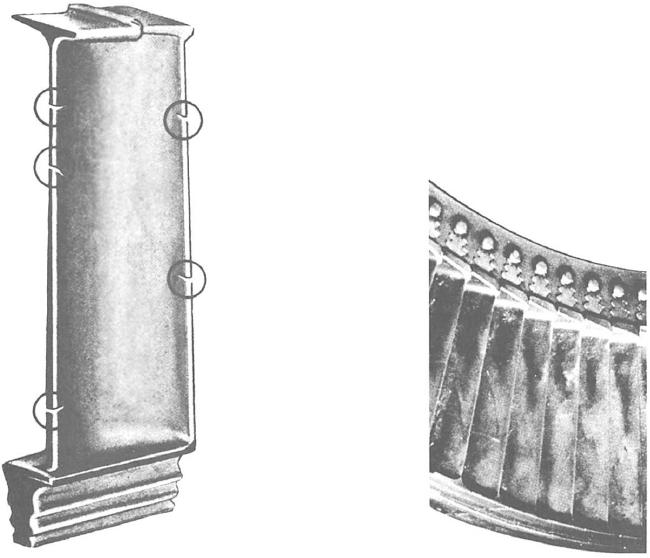

in any area of the blade. Figure 10-11 shows an

Sulfidation is high-temperature corrosion.

example of unacceptable sulfidation of turbine blades.

Sulfidation starts with the excessive levels of sodium

and sulfur in the air and fuel mixture entering the

engine. This type of environment attacks turbine

Turbine Blades

blades and stator vanes.

Sulfidation first appears

as a rough or crusty surface on the leading edge and

concave surface of the airfoil. It progresses to scaling,

splitting (delamination), and eventual metal loss. The

You may inspect turbine blades on axial-flow

sulfidation process accelerates with an increase in

engines, and clean them in the same manner as

sulfur intake and an increase in engine operating

compressor blades. However, because of the extreme

temperature.

heat under which the turbine blades operate, they

All blades should be inspected for sulfidation.

are more easily damaged. Inspect the turbine blades

This form of corrosion is permissible if evidenced only

for stress rupture cracks and deformation of the

leading edge. See figures 10-12 and 10-13.

Stress rupture cracks usually appear as fine

hairline cracks. These cracks are found on or across

the leading or trailing edge at a right angle to the

edge length. Visible-cracks may range-in length from

one-sixteenth inch upward.

Deformation, due to overtemperature, appears as

waviness along the leading edge. The leading edge

must be straight and of uniform

Figure 10-12.-Stress rupture cracks.

Figure 10-13.-Turbine blade waviness.

10-15