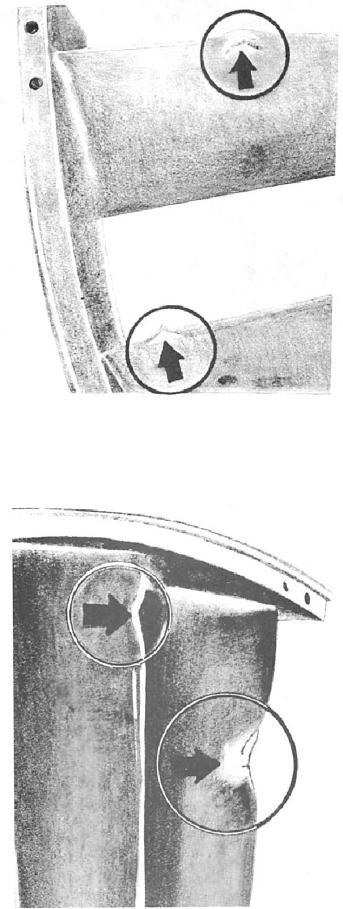

figures 10-6 and 10-7. Concave surfaces of rubber-

filled vanes may have allowable cracks extending

inward from the outer airfoil. These cracks are

allowable provided there is no suggestion of pieces

breaking away. Using a light and mirror, inspect

each guide vane trailing edge and vane body for

cracks and damage caused by foreign objects. Cracks

in the vane body are cause for rejecting the entire

weld.

COMBUSTION SECTION

REPAIRS

The combustion section can be removed,

repaired, or replaced in part or entirely depending on

the extent of damage encountered. The combustion

section consists of liners, support duct, outer and

inner case, and the first stage turbine nozzle

assembly. Most repairs to this section are

accomplished by welding or replacement of

components.

Combustion Chamber Liners

Inspect combustion chamber liners for cracks by

Figure 10-6.-Guide vane trailing edge before

using dye penetrant or the fluorescent penetrant

method of inspection. Cracks con-verging so that

metal could break loose or any loose, cracked, or

damaged swirl vanes are cause for rejecting a liner.

Remove liners having buckled areas in a weld seam.

Areas that have more than a three-sixteenths-inch

wave, which does not include the weld seam, require

removal from service. See figure 10-8.

Combustion chamber liners may be retained in

service with some flaws. For example, liners with

cracks less than 0.125 inch long starting from

combustion air holes (no more than three per sec-

tion) may remain in service. Liners with radial or

circumferential cracks less than 0.750 inch long

extending from or around the crossover tubes or

igniter plug bosses may also remain in service. You

may reuse combustion liners that are burned, except

when burned in the area identified in item 5 of figure

10-8. Rework cracked deflectors to remove the

cracked area by blending or cutting before reuse.

Burning of the cooling louver must not exceed two

tabs totally burned or a total area of two tabs per

liner.

Combustion Chamber Support

Figure 10-7.-Guide vane trailing edge after

Cracks in the combustion chamber support can

be repaired by inert-gas fusion welding.

10-10