emery cloth. Use a medium stone for areas

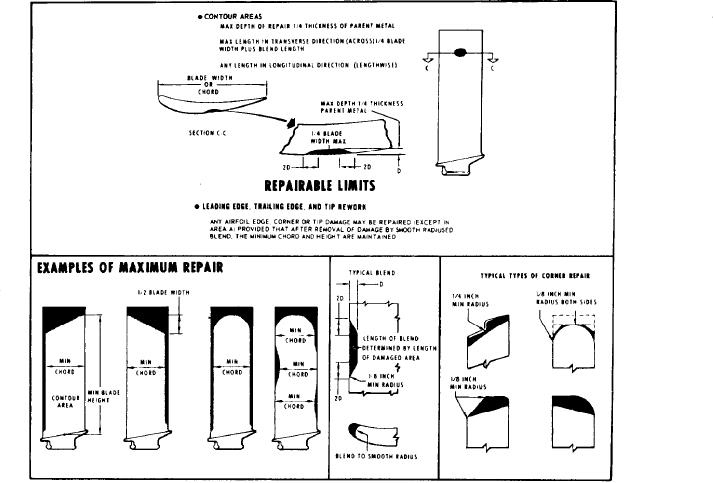

in the MIM. Figure 10-4 illustrates representative

containing small nicks and dents.

repairable limits. Figure 10-5 shows examples of

blade repairs.

Use fine emery cloth and/or a fine abrasive

stone to polish the reworked area. Polish until the

When working on the inner half of the air-

finish looks and feels like the original. If two

foil, you should treat damage with extreme

blended areas overlap to form a sharp point or

caution. Make no attempt to remove damage by

ridge, blend out the point or ridge. Blend the

straightening. Inspect repaired compressor blades

contour surfaces with a medium stone and finish

by dye check, magnetic particle inspection, or

with emery cloth and/or a fine abrasive stone. The

by fluorescent penetrant inspection methods.

finished repair should be as much like the original

Remove all traces of the damage. All surfaces

must be smooth. All repairs must be well blended.

finish as possible.

No cracks of any extent are tolerated in any area.

Front compressor blades that require replace-

Bowed or bent blades are not reused. If gauges

ment are replaced by blades having the same

are not available, the repaired blades are aligned

moment balance code. The moment balance codes

and compared with a new blade of the same stage.

are marked on the front face of the root of the

blade. At the original buildup of the compressor

Use a smooth file when removal of con-

rotor discs and blades, a set of blades coded

siderable amounts of material is necessary. File

according to individual moment were installed.

or blend at right angles to the width of the blade.

The installation on the disc minimizes the static

When you cannot reach the damaged area with

imbalance due to variations in the blade moment.

a file, use course emery cloth. Use a medium stone

The blades are numbered in clockwise sequence,

on areas that have been reworked with a file or

Figure 10-4.-Repairable limits and examples of maximum repair.

10-8