replacement are head thickness and width. If the

head is too thin or too narrow, it might not be

strong enough to bear the load imposed on it. If

the head is too thick or too wide, it might extend

so far that it interferes with the movement of

adjacent parts.

AN bolts come in three head styles--hex head,

clevis, and eyebolt. NAS bolts are available in

countersunk, internal wrenching, and hex head

styles. MS bolts come in internal wrenching and

hex head styles. Head markings indicate the

material of which standard bolts are made. Head

markings may indicate if the bolt is classified as

a close-tolerance bolt. See figure 2-17. Additional

information, such as bolt diameter, bolt length,

and grip length, may be obtained from the bolt

part number. Refer to the Structural Hardware

Manual, NAVAIR 01-1A-8, for complete identifi-

cation of threaded fasteners.

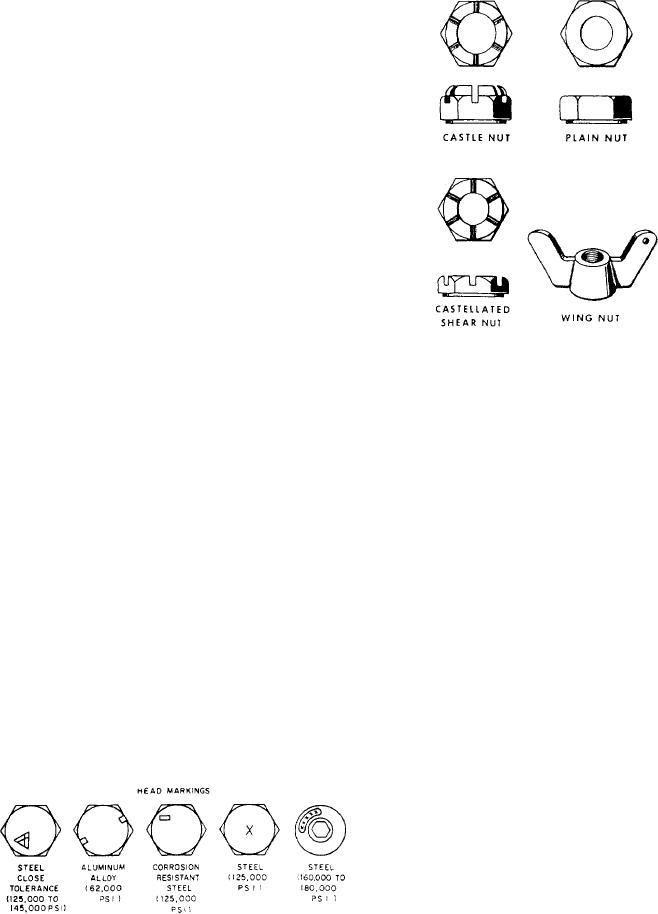

Figure 2-18.-Non-self-locking nuts.

Nuts

Aircraft nuts may be divided into two general

only. They must not be used in installations where

groups: non-self-locking and self-locking nuts.

tension stresses are encountered.

Plain hex nuts have limited use on aircraft

Non-self-locking nuts are those that must be

safetied by external locking devices, such as cotter

structures. They require an auxiliary locking

pins, safety wire, or locknuts. The locking feature

device such as a check nut or a lock washer.

Use wing nuts where the desired tightness can

is an integral part of self-locking nuts.

be obtained by the fingers and where the assembly

NON-SELF-LOCKING NUTS.-- The most

is frequently removed. Wing nuts are commonly

common of the non-self-locking nuts are the castle

used on battery connections.

nut, the plain hex nut, the castellated shear nut,

SELF-LOCKING NUTS.-- Self-locking nuts

and the wing nut. Figure 2-18 shows these non-

provide tight connections that will not loosen

self-locking nuts.

Castle nuts are used with drilled-shank AN

under vibrations. Self-locking nuts approved for

hex-head bolts, clevis bolts, or studs. They are

use on aircraft must meet critical specifications.

These specifications pertain to strength, corrosion

designed to accept a cotter pin or lockwire for

resistance, and heat-resistant temperatures. Use

safetying.

new self-locking nuts each time components are

Castellated shear nuts are used on such parts

as drilled clevis bolts and threaded taper pins.

installed in critical areas throughout the entire air-

They are normally subjected to shearing stress

craft. Self-locking nuts are found on all flight,

engine, and fuel control linkage and attachments.

There are two general types of self-locking nuts.

They are the all-metal nuts and the metal nuts with

a nonmetallic insert to provide the locking action.

The elastic stop nut is constructed with a

nonmetallic (nylon) insert, which is designed to

lock the nut in place. The insert is unthreaded and

has a smaller diameter than the inside diameter

of the nut. Its use is limited to engine cold

sections, s i n c e high heat could melt the

nonmetallic insert.

Self-locking nuts are generally suitable for

reuse in noncritical applications provided the

Figure 2-17.-Bolt head markings.

2-14