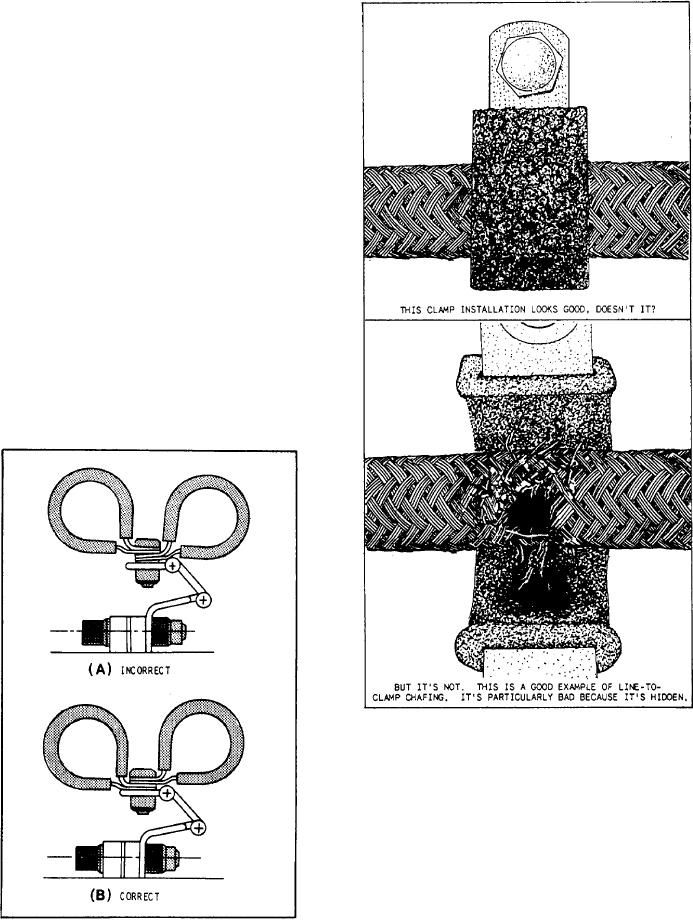

part of the clamps from cutting or chafing the

supported line. Carefully inspect clamps for

proper installation. Figures 2-21 and 2-22 shows

two examples of correct and incorrect installa-

tions, Figure 2-23 shows how improperly installed

or wrong size clamps hide the damage they cause.

SAFETY METHODS

Safetying is a process of securing all aircraft

bolts, nuts, capscrews, studs, and other fasteners.

Safetying prevents the fasteners from working

loose due to vibration. Loose bolts, nuts, or

screws can ruin engines or cause parts of the air-

craft to drop off. To carry out an inspection on

an aircraft, you must be familiar with the various

methods of safetying. Careless safetying is a sure

road to disaster. Always use the proper method

for safetying. You should always inspect for pro-

per safetying throughout the area in which you

are working.

There are various methods of safetying aircraft

parts. The most widely used methods are safety

Figure 2-23.-Hidden damage from improperly installed

clamp.

wire, cotter pins, lock washers, snap rings, and

special nuts. Some of these nuts and washers have

been described previously in this chapter. You

should know how to use safety wire and cotter

pins.

Safety Wiring

Safety wiring is the most positive and satisfac-

Figure 2-22.-Examples of (A) incorrect and (B) correct in-

stallation of Adell clamp.

tory method of safetying. It is a method of wiring

2-17