threads have not been damaged. If the locking

material has not been damaged or permanently

distorted, it can be reused.

NOTE: If any doubt exists about the

condition of a nut, use a new one!

Installation of Nuts and Bolts

It is of extreme importance to use like bolts

in replacement. In every case, refer to the

applicable maintenance instruction manual and

illustrated parts breakdown. Be certain that each

bolt is of the correct material, size, and grip

length. Examine the markings on the head to

determine whether a bolt is steel or aluminum

alloy. This knowledge is especially important if

you are to use the bolt in the engine hot section.

Use washers under the heads of both bolts and

nuts unless their omission is specified. A washer

guards against mechanical damage to the material

being bolted. A washer also prevents corrosion

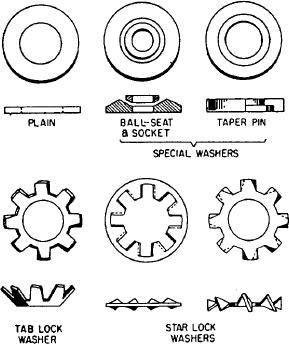

Figure 2-19.--Various types of washers.

of the structural members. An aluminum alloy

washer used under the head and nut of a steel bolt

securing aluminum alloy or magnesium alloy

Sufficient friction is provided by the spring

members will corrode the washer rather than the

action of the washer to prevent loosening of the

members. Steel washers should be used when

nut because of vibration. Lock washers must not

joining steel members with steel bolts.

be used as part of a fastener for primary or

Whenever possible, the bolt should be placed

secondary structures.

with the head on top or in the forward position.

This positioning helps prevent the bolt from

The star lock or shakeproof washer is a round

slipping out if the nut is accidentally lost.

washer made of hardened and tempered carbon

steel, stainless steel, or Monel. This washer can

WASHERS

have either internal or external teeth. Each tooth

is twisted, one edge up and one edge down. The

Washers used in aircraft structures may be

top edge bites into the nut or bolt, and the bottom

grouped into three general classes: plain, lock

edge bites into the working surface. It depends

washers, and special washers. Figure 2-19 shows

on spring action for its locking feature. This

some of the most commonly used types.

washer can be used only once because the teeth

become compressed after being used.

Plain Washers

Tab lock washers are round washers designed

with tabs or lips that are bent across the sides of

Plain washers are widely used under AN hex

a hex nut or bolt to lock the nut in place. There

nuts to provide a smooth bearing surface. They

are various methods of securing the tab lock

act as a shim in obtaining the correct relationship

washer to prevent it from turning. An external

between the threads of a bolt and the nut. They

tab bent downward 90 degrees into a small hole

also aid in adjusting the position of castellated

in the face of the unit, an external tab that fits

nuts with respect to drilled cotter pin holes in

a keyed bolt, or two or more tab lock washers

bolts. Plain washers are also used under lock

connected by a bar are some of the present

washers to prevent damage to surfaces of soft

methods used. Tab lock washers can withstand

material.

higher heat than other methods of safetying. The

washer can be used safely under high vibration

Lock Washers

conditions. Use tab lock washers only once

Lock washers are used whenever the self-

because the tab tends to crystallize when bent a

locking or castellated-type nut is not used.

second time.

2-15