The most common methods of oil temperature

indicators are a thermocouple-type fitting or an

oil temperature bulb.

Vents

Vents are lines or openings to the atmosphere

in the oil tanks or accessory cases of the engine.

The purpose of the vent in an oil tank is to keep

the pressure within the tank from rising above or

falling below that of the outside atmosphere.

However, the vent may be routed through a

pressure relief valve that keeps pressure on the oil

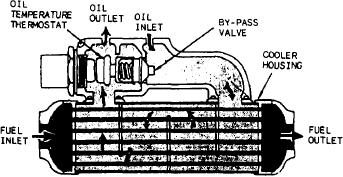

Figure 5-13.-Fuel-oil heat-exchanger type of cooler.

system to assure positive flow.

In the accessory case, the vent (or breather)

is a screen-protected opening that allows

Oil Jets

accumulated air pressure to escape. The scavenged

oil carries air into the accessory case, and this air

must be vented. Otherwise, the pressure buildup

The oil jets (or nozzles) are located in the

within the accessory case would stop the flow of

pressure lines next to or within the bearing

oil draining from the No. 1 bearing. This oil

compartments and rotor shaft couplings. The oil

would be forced past the rear bearing oil seal and

from these nozzles is delivered as an atomized

into the compressor housing. Oil leakage could

spray. Some engines use an air-oil mist type of

nozzle spray. This air-oil mist is produced

cause any of several problems, including high oil

by tapping high-pressure bleed air from the

consumption, cockpit air contamination, or a fire.

compressor and mixing it with the oil. This

An oil leakage around the combustion area

method is adequate for ball and roller type of

or turbine area could cause burning and engine

bearings; however, the solid oil spray method is

failure.

The screened breathers are usually located in

better.

the front center of the accessory case to prevent

Some engines have "expendable oil" jets to

oil leakage through the breather. Some breathers

lubricate the bearings supporting the turbine rotor

have a baffle to prevent oil leakage during flight

shaft. The air-oil mist from such jets is not

maneuvers.

returned to the tank, but is discharged overboard.

A vent that leads directly to the No. 1 bear-

ing compartment may be used in some engines.

This vent equalizes pressure around the front

Gauge Connections

bearing surface. Then the lower pressure at the

first compressor stage will not force oil past the

Gauge connections are used in the oil system

No. 1 bearing rear carbon oil seal and into the

for oil pressure and oil temperature. The oil

compressor.

pressure gauge is usually a necessity in all systems

to measure the pressure of the lubricant. This is

Oil System Seals

done as it leaves the pump on its way to the oil

jets. Since oil pressure is the best indication that

Any system containing fluids need some type

the system is operating properly, the oil pressure

of seal to prevent fluid loss. The importance

gauge is vital.

of oil seals cannot be overemphasized! An

improperly installed or leaking seal in the oil

The oil pressure gauge connection is always

located in the pressure line between the pump and

system could cause bearing failure, fire, or cockpit

fumes. This could result in loss of aircraft or

the various points of lubrication. The oil

LIFE. There are three types of seals used in jet

temperature gauge connection may be located in

engine oil systems--synthetic, carbon, and

either the pressure or the scavenge line. However,

labyrinth.

the scavenge line is preferred, since this location

permits a more accurate indication of the actual

SYNTHETIC SEALS.-- Seals, packings, and

bearing temperatures, as the temperature of the

O-rings are used where metal-to-metal contact

oil is shown shortly after it leaves the bearings.

5-15