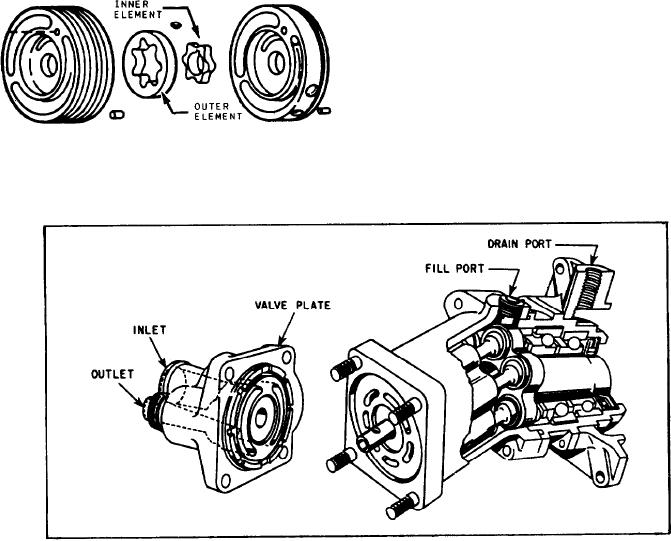

A set of gerotor pumping elements is shown

output pressure of the pump by bypassing oil back

in figure 5-7. Each set of gerotors is separated by

to the pump inlet. Also notice the location of the

a steel plate, making each set an individual

shaft shear section, which will allow the shaft to

pumping unit. Each set consists of an inner

shear if the gears should seize.

element and an outer element. The small star-

GEROTOR OIL PUMP.-- The gerotor pump

shaped inner element has external lobes fitting

usually has a single element for oil feed and several

within and matching with the outer element,

which has internal lobes. The small element

elements for scavenging oil. Each of the elements,

pinned to the pump shaft acts as a drive for the

pressure and scavenge, is almost identical in

outer free-turning element. The outer element fits

shape. However, the capacity of the elements is

within its steel plate, having an eccentric (not

controlled by varying the size of the gerotor

having the same center) bore. In some engine

elements. The pressure element has a pumping

models, the oil pump has four elements, one for

capacity of 3.1 gpm (gallons per minute) com-

oil feed and three for scavenging. In other models,

pared to a 4.25-gpm capacity for the scavenge

elements. So the pressure element must be smaller

pumps have six elements, one for feed and five

for scavenge. In each case, the oil flows as long

since the elements are all driven by a common

as the engine shaft is turning.

shaft. Engine rpm determines oil pressure, with

a minimum pressure at idling speed and maximum

PISTON OIL PUMP.-- The piston lubrica-

pressure at maximum engine speed.

tion pump is always a multiplunger type. Output

of each piston supplies a separate jet. Oil drained

from the points of lubrication is scavenged by a

separate pump element. The piston-type pump

(fig. 5-8) is used less than either of the other types.

Valves

Valves control the pressure and flow of oil in

the lubrication system. There are three types of

valves common to oil systems that are discussed

in this text. They are relief valves, check valves.

Figure 5-7.-Gerotor pumping element.

and bypass valves.

Figure 5-8.-Axial piston pump.

5-11