(last-chance filters) for straining the oil just before

There are several types of filters used for

it passes through the spray nozzles onto the bear-

filtering the lubricating oil. The filtering elements

ing surfaces.

come in a variety of configurations. The parts of

a main oil filter-include a-housing, which has an

Chip Detectors

internal relief valve and a filtering element.

The magnetic-chip detector is a metal plug

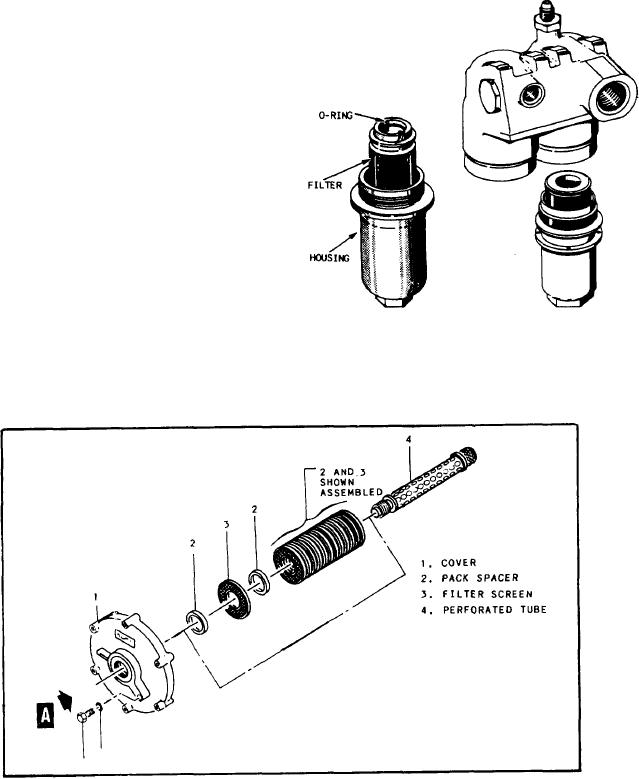

DISK-TYPE FILTER.-- The disk filter (fig,

with magnetized contacts, and is placed in the

5-10) consists of a series of spacers and screens.

The screens and spacers are stacked alternately

in the housing. The spacers direct oil through the

screens as it flows through the assembly. The

screen mesh (usually measured in microns)

determines the size of foreign matter allowed to

pass through the filter.

MICRONIC-TYPE FILTER.-- The micronic

filter is similar to the cartridge filter used on a

car's oil filter, as shown in figure 5-11. It uses

either a paper or metal cartridge type of oil filter.

The paper filtering element is removed and

replaced, while the metal type is cleaned and

reused.

Each of the oil filter types mentioned in the

preceding paragraphs has certain advantages. The

filter types just discussed are generally used as

main oil filters. These filters strain the oil as it

leaves the oil pump. In addition to main oil filters,

there are also secondary filters throughout the

system. For instance, there may be a finger screen

filter to trap large metal pieces before the magnetic

Figure 5-11.-Filtering assembly.

drain plug. Also, there are the fine mesh screens

Figure 5-10.-Spacers-and-screens oil filter.

5-13