prevents proper sealing. These seals come in many

LABYRINTH SEALS.-- Labyrinth seals

different shapes and sizes and are not reusable.

contains series of knifelike, soft metal edges that

It is important to use the proper seal (identified

ride very close to a steel surface. A certain amount

by correct part number) for the specific installa-

of air, taken from the compressor, forced between

tion. NEVER use a seal, packing, or O-ring

the steel surface and soft metal edges prevent oil

because they look alike. A seal designed to have

leakage between sections. These seals were used

excellent sealing characteristics in one environ-

as main bearing seals in earlier engines. These seals

ment could be hazardous when used in another.

are made of very soft metal and used at main bear-

Some seals swell when contacted with MIL-L-7808

ing areas. Small nicks in the seal can cause major

oil, while others deteriorate completely.

oil leaks and premature engine changes.

CARBON SEALS.-- Carbon seals are used to

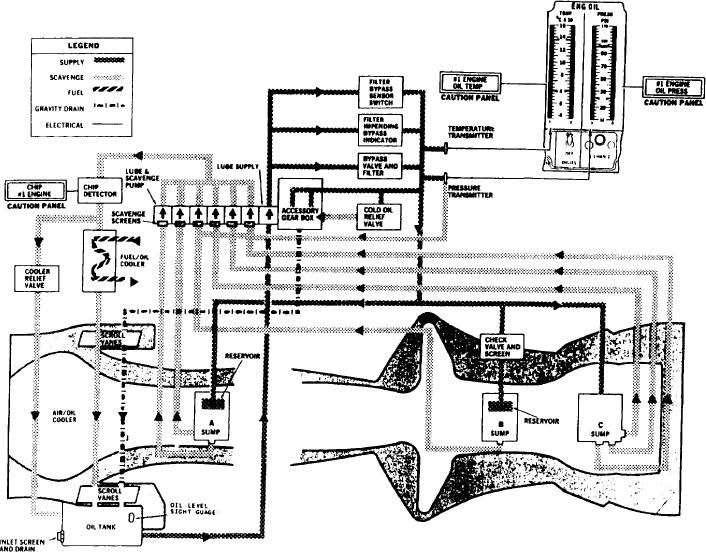

ENGINE OIL SYSTEM DESCRIPTION

contain the oil in the bearing areas. Carbon seals

form a sealing surface by having a smooth carbon

The engine oil system shown in figure 5-14 is

seal rub against a smooth steel surface (faceplate).

a representative engine of a self-contained,

All carbon seals are preloaded. Preloading means

pressurized, recirculating, dry-sump system. It

the carbon seal is held against the steel surface.

consists of the following systems and parts:

Three common methods of preloading carbon

seals are spring tension, centrifugal force, and air

1. Tank

pressure.

2. Oil pressure and scavenge pump

Figure 5-14.-Engine oil system schematic.

5-16