necessary, clean the barrel and shell threads with

a die. Visually inspect the exposed ceramic

section. Any cracks are cause for rejection.

The functional testing of the capacitor

discharge ignition system is a simple operation.

WARNING

You should exercise caution while per-

forming this test. Do not come into contact

with the igniter plugs or leads while the

power is on in the ignition system. Some

systems have voltages up to 28,000 volts

or more. These high voltages could cause

serious injury or death. Prevent fuel or fuel

fumes from gathering under the engine

while the igniter plugs are being ground

tested.

Perform a dry run of the engine (operate the

ignition system). Listen at the tailpipe. You can

determine if the unit is working by listening for

the spark. Another way is to remove the spark

igniters, leave them hanging on the high-tension

leads, and operate the ignition system. The spark

can be seen at the plug if the unit is working. The

spark should be brilliant and accompanied by a

sharp report.

STARTING SYSTEMS

Starting a jet engine requires rotating the

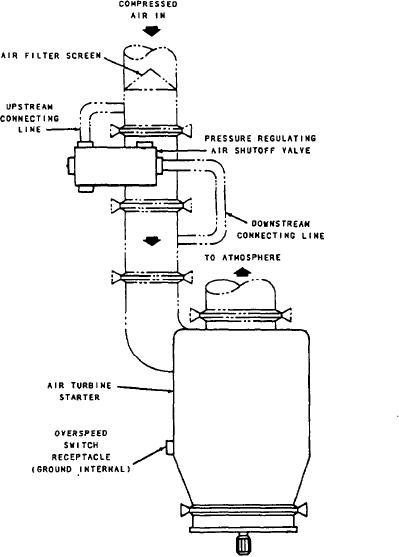

Figure 6-8.-Air turbine starting system.

compressor fast enough to begin the engine

combustion cycle. Starting systems must be

capable of providing both high starting torque and

Compressed air, supplied to the scroll inlet,

high speed. High starting torque is required to

is sent to the turbine wheel by the nozzle in the

overcome the large amount of weight of the engine

scroll assembly. The reduction gear system

rotor. High speed is required to increase rotor rpm

transforms the high speed and low torque of the

until the rotor is self-sustaining. There are several

turbine wheel to low speed and high torque at the

ways to accomplish these objectives. The follow-

output shaft. An overspeed switch mechanism is

ing paragraphs describe four methods. They are

used to limit maximum rotational speed. When

the air turbine starter, the direct turbine impinge-

the desired starter rotational speed is reached, the

ment starter, the electrical starter, or the hydraulic

fly weights in the governor assembly will open the

starter.

limit switch. This section sends a signal that shuts

off the supply of air. At a higher, predetermined

Air Turbine Starter

rotational speed, the overrunning clutch assembly

disengages the output shaft from the rotating

The air turbine starter is a lightweight unit for

assembly.

starting engines with compressed air. The starter

is a turbine air motor equipped with a radial

Turbine Impingement Starter

inward-flow turbine wheel assembly, reduction

gearing, splined output shaft, and a quick-

Some naval aircraft are started by means of

detaching coupling assembly. See figure 6-8.

low-pressure air directed onto the turbine or

6-11