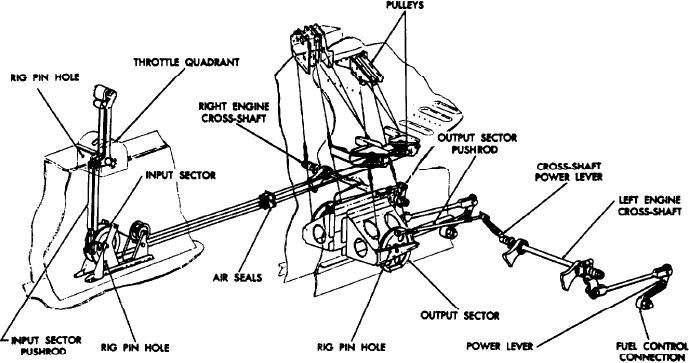

While rigging the fuel selector, power control,

3. Have all of the appropriate caps and plugs

and shutoff valve linkages, you should follow the

available to prevent the contamination of open

step-by-step procedures for the particular aircraft

fuel lines during component replacement.

model being rigged. The cables should be rigged

4. Have parts bags and tags available to keep

with the proper tension with the rigging pins

all removed nuts, bolts, and washers in one

installed. The pins should be removed without any

location, and be sure to tag all fuel lines before

binding; if they are hard to remove, the cables

removal. This makes reinstallation much easier

are not rigged properly and should be rechecked.

and less confusing.

The power lever should have the proper cushion

5. If the removed component is to be turned

at the IDLE and FULL POWER positions. The

into supply, make sure it is purged and filled with

pointers or indicators on the fuel control should

an approved preservative before turn-in.

be within limits. You must take all of these things

into consideration while rigging or adjusting the

RIGGING AND ADJUSTING

parts of the fuel system. Also, the fuel selectors

must be rigged so that they have the proper travel

This section covers some of the basic

and will not restrict the fuel flow to the engines.

inspections and procedures to be used in the

Rigging the fuel control of a turbojet engine

rigging and adjusting of fuel controls, fuel

is an exacting job. The power lever assembly and

selectors, and fuel shutoff valves. Inspect all bell

its related linkage provide manual control of the

cranks and rod bearings for looseness, cracks, and

engine thrust. The power lever assembly is located

corrosion. Particular attention should be given to

in the cockpit, and its related mechanical linkage

the rod and bell cranks where the bearing is

connects it with the fuel control unit of the engine.

staked. This area is subject to stress cracking and

Positioning the power lever at any selected setting

corrosion. The adjustable rod ends should be

mechanically actuates the linkage to the fuel

inspected for damaged threads and the number

control unit, resulting in the desired engine thrust.

of threads remaining after final adjustment. The

Modern jet aircraft use various power lever

drums should be inspected for wear, and the cable

control systems. One of the common types is the

guards should be checked for proper positioning.

cable and rod system. In this system, you will find

If the cables have been loosened, the tension

bell cranks, push-pull rods, drums, fairleads,

should be set.

Figure 4-29.-Engine power control system rigging.

4-40