If it is too cold, the oil will resist movement

3. Water resistance. In some cases, a grease

between the parts and flow too slowly for proper

that is insoluble in water is required. In other

lubrication. If the oil pressure is too low, it will

cases, the grease must be resistant only to weather-

not supply enough oil to the bearing for proper

ing or during washing.

cooling. If the pressure is too high, it may cause

4. Satisfactory performance in use. The grease

high-speed antifriction bearings to skid and not

must perform satisfactorily in the equipment and

roll properly.

under the conditions it was intended.

It would be impossible to cover all the

different parts of every type of engine oil system

Properties of greases vary with the type of

in use today. Therefore, this text presents a

soap used in manufacturing. Military specifica-

representative sample of various parts common

tions specify the operating conditions or applica-

to different types of oil systems.

tions. Table 5-2 contains information on some of

the most frequently used greases.

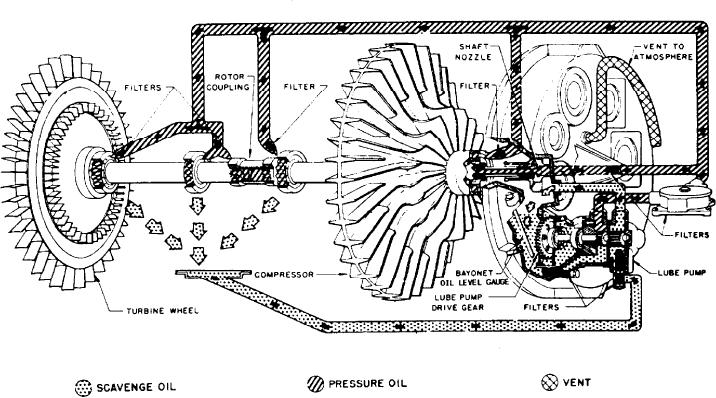

TYPES OF LUBRICATION SYSTEMS

Engines use a wet-sump, dry-sump, or a

LUBRICATION SYSTEMS

combination of both as lubricating systems. Wet-

sump engines store the lubricating oil in the engine

Oil systems used in jet engines are relatively

or gearbox. Dry-sump engines use an external

simple in design and operation, but their

tank mounted on the engine or somewhere in the

function is important. The principal purposes of

aircraft structure near the engine. Under the dry-

the oil system are the same as those covered under

sump lubrication system is another type called the

lubricating oils--to provide an adequate supply

hot tank system. You should know the similarity

and operation of these systems.

pressure and temperature, to remove heat from

the engine, and to remove contaminants from the

Wet-sump System

system and deposit them in the filters.

The ability of the oil to lubricate correctly

Engines needing a limited supply of oil and

depends upon its temperature and pressure. If the

cooling can use a wet-sump type (fig. 5-1). The

oil is too hot, it will not have enough viscosity.

Figure 5-1.-Wet-sump lubrication system.

5-4