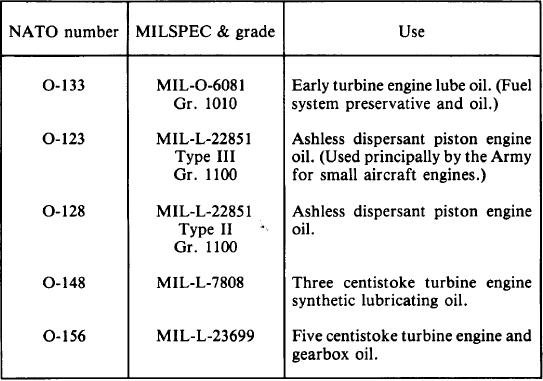

Table 5-1.-Classification of Lubricating Oils

especially where heat is concentrated; for example,

The contamination of oil by engine fuel can

in- the bearing compartments near hot turbine

result from a ruptured fuel-oil cooler. Since the

sections. This carbon eventually breaks off and

fuel system operates at a higher pressure than the

circulates through the engine lubricating system.

lube system, the flow will be into the oil supply.

The presence of fuel in the oil will cause oil

The pieces of carbon are usually not hard enough

or large enough to cause failure of the pumps.

dilution. It also changes the oil properties so the

However, they may be large enough to clog small

oil cannot cool and lubricate the bearings

properly.

filters or nozzles. The presence of sand, dirt, and

Another serious type of contamination is the

metallic particles in the lube system is another

oil itself. Synthetic oil will cloud or form other

source of operational contamination.

Faulty maintenance practices that contaminate

contaminants if stored too long. This is why there

is a shelf life for all synthetic oils. Never use

lubricating systems include using the wrong type,

overaged oil. Follow the applicable instruction for

or mixing oils, and improper servicing. The lube

shelf life of synthetic oil (it is usually 6 months)

system parts of an engine are made of materials

to prevent problems.

based upon the type of oil that is to be used.

Synthetic oils attack the common rubber materials

LUBRICATING GREASES AND

used in the O-ring, seals, and gaskets of lubrica-

THEIR PROPERTIES

tion systems that use mineral-based oil. This

attack causes the material to soften, swell, and

Another type of lubricant ADs should be

lose its ability to seal properly. This condition

familiar with is grease. Grease is used on bearings,

causes the oil to leak from the system.

outside the engine lubricating system, control

The contamination of oil by rust maybe due

arms and linkages, and actuators, The most

to water in the oil system. There is also contaminat-

important requirements of greases are as follows:

ion from storage containers or servicing equip-

1. Stability. It must be free from bleeding

ment. Over time, rust in the lube system will

(separation of oils), oxidation, and changes in

eventually discolor the bearings. Ordinary rust will

consistency during periods of storage and use.

leave a red discoloration on the bearing elements,

2. Noncorrosiveness. The lubricant must not

and black iron oxides will leave a black indica-

tion. These rust particles are not large enough to

chemically attack the various metals and other

material it comes in contact with.

cause pump failure.

5-3