engine, and immediately take corrective action

when an abnormal condition occurs. Performance

of precision work is necessary when maintaining

fire warning systems to ensure their reliability. An

undetected fire may cost the lives of the aircrew

and possibly millions of dollars in aircraft and

equipment.

In multiengined aircraft, a fire warning usually

dictates that the engine be shut down and the fire

extinguished. The least that can happen if there

is an erroneous fire warning is the aircraft will

abort its assigned mission.

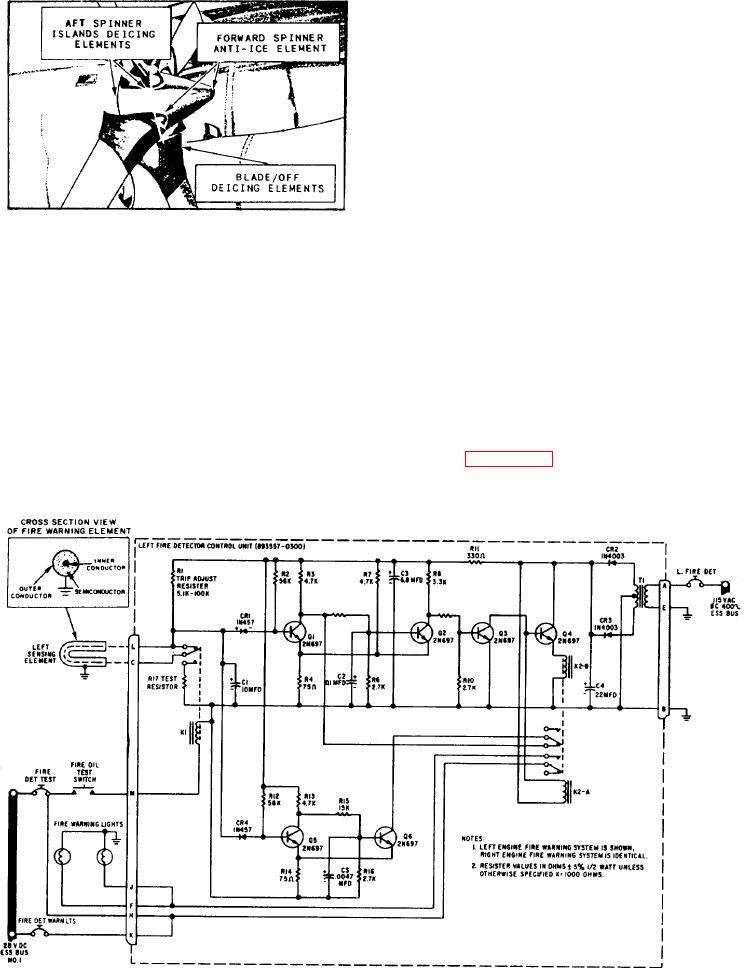

WARNING SYSTEM

The engine fire detector system is an electrical

FIRE WARNING AND

system for detecting the presence of fire or dan-

EXTINGUISHING SYSTEMS

gerously high temperatures in the engine(s) areas.

The system for each engine consists of a control

Learning Objective: Recognize operating

unit, test relay, signal lamp, test switch, and

conditions and characteristics of aircraft

several sensing elements. The detect or uses a

engine fire warning and extinguishing

continuous strip of temperature-sensing elements

systems.

to cover the paths of airflow in the engine com-

Some

turbine engines operate at temperatures

partment. The same engine fire warning systems

of more

than 1,000C. Fuel and oil lines run

are in multiengined aircraft, one for each engine.

with in a

few inches of these extreme temperatures.

Look at figure 5-12. It shows the electrical

For this

reason, you must closely monitor the

schematic for a fire warning system that is

Figure 5-12.-Typical engine fire warning circuit schematic.